Germany's aerodyn launches rotor blade for 11-15 MW turbines

The rotor blade boasts CFRP-GFRP spar caps, a 128-meter rotor diameter, an adjustable design and more.

Source | aerodyn

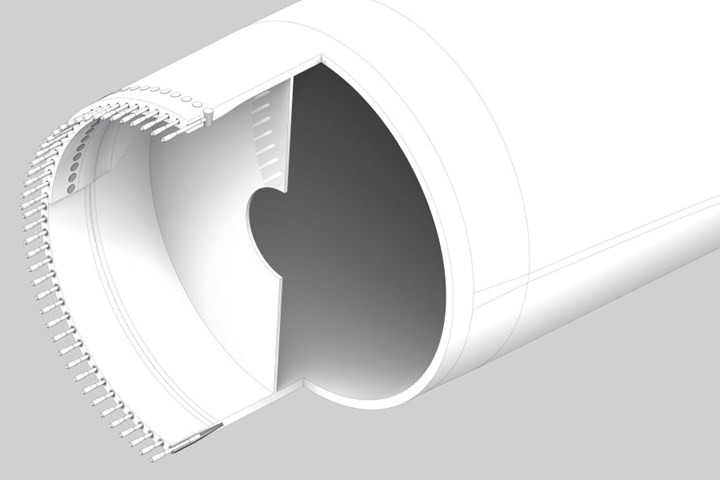

Wind turbine specialist aerodyn Energiesysteme GmbH (Rendsberg, Germany) reports that it has developed a 111-meter TC1B rotor blade for 11-15 MW wind turbines. To reduce the cost of using carbon fiber, aerodyn says the blade design features hybrid CFRP-GFRP spar caps and can be adjusted according to wind turbine specifications and site conditions.

At a rated power of 14,000 kilowatts, aerodyn’s rotor blade design features a 128-meter rotor diameter with a nominal speed of 7.54 rpm and nominal tip speed of 90 m/s. A 1B design class type, the 14-MW blade maintains a 7.018-meter maximum chord and has 4 meters of prebending at the blade tip. Additionally, the BCD blade root length reaches 5,050 millimeters.

The company is currently working on 10-MW offshore wind turbines, as well as a future generation of 15-MW systems. For more information, read aerodyne’s technical data sheet.

Related Content

-

Honda begins production of 2025 CR-V e:FCEV with Type 4 hydrogen tanks in U.S.

Model includes new technologies produced at Performance Manufacturing Center (PMC) in Marysville, Ohio, which is part of Honda hydrogen business strategy that includes Class 8 trucks.

-

High-tension, vertical filament winding enables affordable flywheel energy storage system

French startup Energiestro’s prototype solar energy flywheel-based storage system aims to reduce costs with glass fiber composites and prestressed concrete.

-

Achieving composites innovation through collaboration

Stephen Heinz, vice president of R&I for Syensqo delivered an inspirational keynote at SAMPE 2024, highlighting the significant role of composite materials in emerging technologies and encouraging broader collaboration within the manufacturing community.