FACC to open composites facility in Croatia

The facility will build composite cabin components for commercial and business aircraft.

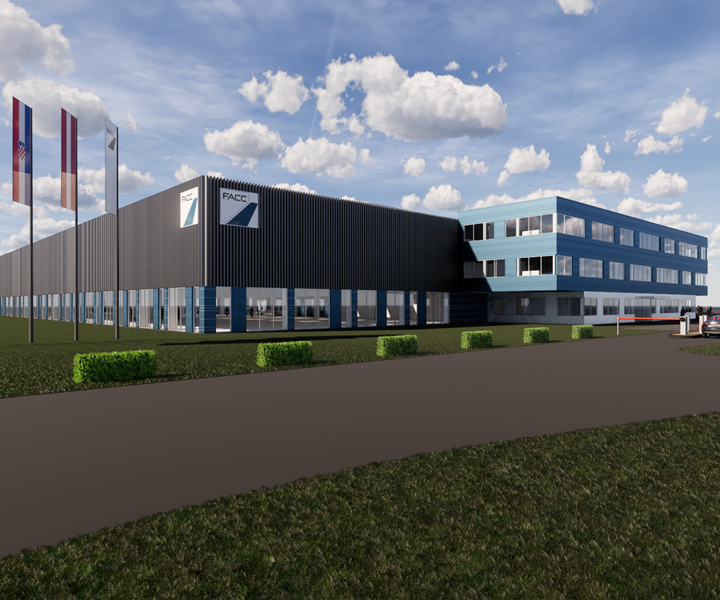

An artist rendering of the new Croatian facility. Source | FACC

FACC (Ried im Innkreis, Austria) has announced plans for a new aerospace composites production facility in Croatia, valued at an investment of around 30 million euros. As a 100% subsidiary of FACC, this new production facility will manufacture lightweight cabin components for commercial and business aircraft using composites technology.

The facility will be located in Jakovlje in the Zagreb district of Croatia. Construction on the 12,200 square-meter facility is scheduled to begin this year with expectations of starting production by March 2021. When fully operations, it reportedly will employ more more than 600 people.

FACC says it chose Croatia as a strategic partner for the country’s established industry, proximity to FACC’s Austrian facilities and highly skilled and trained workforce. The company plans to show its commitment to the region by establishing a dual training system for aviation professions, partnering with local technical schools.

Representatives of FACC and the Croatian government announce FACC's plans to build a high-tech composite plant in Croatia (from left to right): Stjepan Kožić, head of Zagreb County; Sanja Borovec, Mayor of Municipality Jakovlje; Darko Horvat, Minister of Economy, Entrepreneurship and Crafts Republic of Croatia, FACC CEO Robert Machtlinger; Andrej Plenković, Prime Minister Republic of Croatia; Ruguang Geng, chairman of FACC supervisory board; Zdenko Lucić, State Secretary Ministry of Economy, Entrepreneurship and Crafts Republic of Croatia. Source | FACC

“This expansion represents a strategic investment for our company, and we are confident that the FACC Croatia Production Center of Competence will substantially contribute to our corporate strategy of quality and efficiency leadership,” says Robert Machlinger, CEO of FACC. “This green field investment offers us the opportunity to set up a best-in-class aerospace facility, implementing leading-edge technology, automation and Industry 4.0 methods.”

Related Content

-

Industrializing additive manufacturing in the defense/aerospace sector

GA-ASI demonstrates a path forward for the use of additive technologies for composite tooling, flight-qualified parts.

-

Development of a composite liquid hydrogen tank for commercial aircraft

Netherlands consortium advances cryogenic composites testing, tank designs and manufacturing including AFP, hybrid winding, welding of tank components and integrated SHM and H2 sensors for demonstrators in 2025.

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

.jpg;width=70;height=70;mode=crop)