Expansion begins at Hexcel engineered core operations plant in Morocco

The site will double in size by 2023 to meet increasing demand for lightweight advanced composites from aerospace customers.

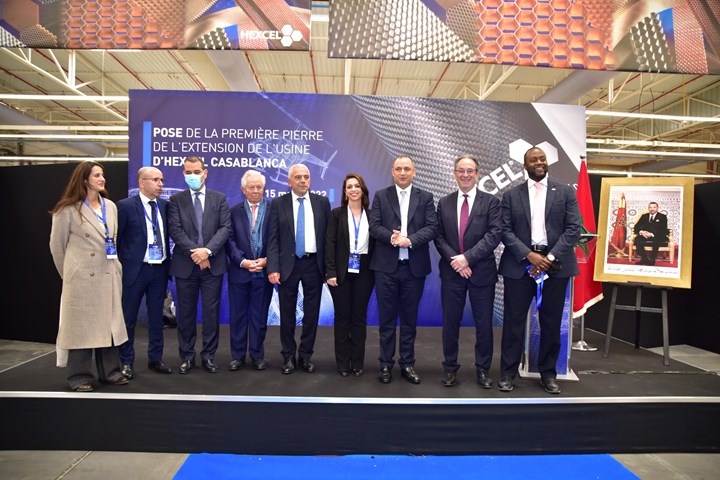

Photo Credit: Hexcel Corp.

Hexcel Corp. (Stamford, Conn., U.S.) hosted customers and public officials on March 15 at its manufacturing site in the Midparc Free Trade Zone in Casablanca as the company broke ground on an expansion that will double the size of its existing engineered core manufacturing operation in Morocco to meet increased demand from aerospace customers for lightweight advanced composites.

The expansion, announced in September 2021, is expected to be completed in early 2023. The plant size will double to 24,000 square meters and employment is expected to increase from 120 to 400 people once completed.

“We are pleased to celebrate this milestone with our customers and with the local community. The increased demand for lightweight, aerodynamic, advanced composites is growing, and our customers including Safran, Airbus, Airbus Atlantic, Boeing and Spirit AeroSystems have shown confidence in our ability to meet that demand,” Thierry Merlot, Hexcel president, aerospace for Europe, MEA/AP & Industrial said at the event. “We appreciate the support from them as well as from the Ministry and everyone in the local community who continue providing us with the opportunity to further our investment in Morocco. The very successful establishment of Hexcel, the qualification of the workforce, the support of the state and the proximity of our customers have been real assets to launch this extension of our site in Casablanca.”

The Casablanca facility was originally built as part of Hexcel’s ongoing worldwide investment to create a diversified and robust global supply chain to support aerospace customers’ growing demand for engineered core. At the plant, Hexcel says it transforms lightweight honeycomb materials into engineered core parts to reinforce structures in the aerospace industry, particularly for aircraft, engine nacelles and helicopter blades.

“The groundbreaking of the extension of the Hexcel plant at Midparc marks the strong recovery of the aerospace sector in Morocco after the downturn caused by COVID-19,” Hamid Benbrahim El Andaloussi, president of Midparc, added. “In addition, it reflects a renewed confidence by Hexcel, a leader in advanced composite materials, in Morocco and in Midparc.”

This announcement adds to Hexcel breaking ground for a new flagship facility in Utah, reported in October 2021.

Related Content

-

Airbus video highlights RACER compound helicopter first flight

Launched as part of a Clean Sky 2 program, a compound design — rotor, split fixed-wing, propulsive propellers — uses composites to cut fuel consumption and emissions by 20%.

-

Cutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

-

Melker of Sweden accomplishes sea kayak with 100% sustainable composite construction

Built with ampliTex flax fabrics, a solid cork core and Sicomin plant-based resins, the company’s Värmdö kayak model highlights an environmentally conscious design for paddlers of all levels.