Conbility tape placement head installed at University of Limerick

The PrePro 3D system combines laser-assisted thermoplastic tape placement with IR-assisted thermoset prepreg placement.

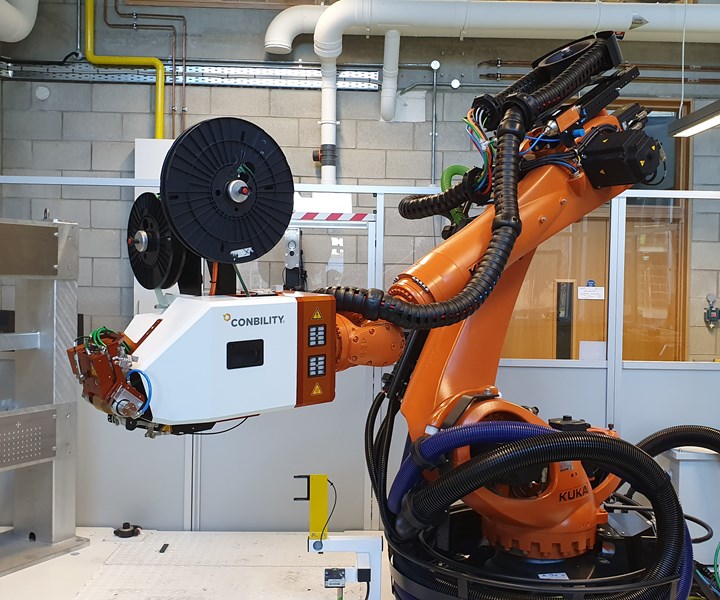

The multifunctional PrePro3D head installed at the existing robot system at the University of Limerick. Source | Conbility GmbH

Conbility GmbH (Aachen, Germany) announced that it has recently delivered a modular 3D Tape Placement Applicator for tape winding and tape placement to the Bernal Institute of the University of Limerick, Ireland.

According to Conbility, the PrePro 3D system combines three technologies in one modular system: laser-assisted thermoplastic tape placement, infrared (IR) assisted thermoset prepreg placement, and the unwinding of backing paper and dry fiber placement. The system installed in Limerick is equipped with an infrared heating source but Conbility says it can be easily upgraded with a high-power diode laser system.

The JEC-award-winning PrePro 3D tape placement and winding applicator is available as modular tool with decentral control system and HMI (including closed-loop control of energy input into the processing zone) for the “plug-in” implementation in existing robot systems or machine systems by standard interfaces for the communication with the master control system. Conbility provides the single applicator as well as turn-key ready systems including the robot and handling systems as well as the laser-safe manufacturing cell.

The PrePro 3D head is based on 25 years of development work at the Fraunhofer Institute for Production Technology (IPT) regarding laser-assisted tape processing with in-situ consolidation. Since 2018, Conbility GmbH has been a contract partner of the Fraunhofer Institute for Production Technology, IPT for the commercialization and further development of the PrePro 2D and PrePro 3D tape placement systems.

“… [This system] will significantly enhance our capability to conduct research on processing of novel composite structures, allowing us to realize and validate the novel designs developed by our research team for a variety of high-performance applications. We already have a number of projects underway which will use this equipment, in conjunction with the SFI Confirm Smart Manufacturing Research Centre and look forward to the future research opportunities it will enable,” says Dr. Ronan O’Higgins, Bernal Institute, University of Limerick.

Funding for this equipment was provided by Science Foundation Ireland (SFI) for funding Spatially and Temporally VARIable COMPosite Structures (VARICOMP).

Related Content

-

Hitachi Rail chooses Roboze printers, materials including carbon fiber/PEEK for railway spare parts

The Roboze ARGO 500 will be used at Hitachi Rail factories in Naples, Italy and Maryland, U.S. to reduce cost and delivery times for prototypes and spare parts.

-

Large-format AM speeds plug production for manufacture of composite boat molds

Hungarian manufacturer Rapid Prototyping transitioned its conventional foam milling process to 3D printing to produce faster, higher quality, recyclable foam plugs and composite boat molds.

-

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

.jpg;width=70;height=70;mode=crop)