CompPair closes seed funding to advance composite self-healing technology

EPFL spin-off company has launched HealTech which repairs composite damage in one minute by applying heat.

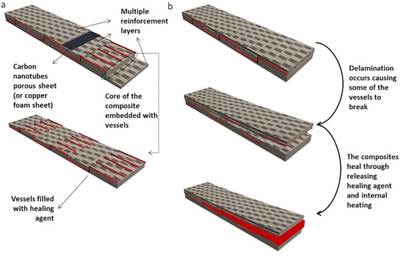

CompPair self-healing prepregs. Photo Credit: CompPair Technologies Ltd.

(Lausanne, Switzerland) is a spin-off from the École polytechnique fédérale de Lausanne (EPFL), which has invented a new composite material able to repair itself — damage from manufacturing, impact, or fatigue can reportedly be easily repaired in only one minute by applying heat. CompPair claims its technology helps to build better products that last longer and produce less waste. Its first product family, HealTech, has already received significant interest in the sports and marine sectors.

The seed round funding of 950,000 Swiss Francs was led by the StartAngels Network and Christian Fischer, CEO and co-founder of Bcomp (Fribourg, Switzerland), a pioneer in sustainable, natural fiber composites, along with valuable contributions from private investors. This seed investment will allow CompPair to continue implementing its HealTech products within the composites industry by extending production capacity and building pilot projects to penetrate new markets. The company will also add new staff in business development, engineering and operations and begin finalizing the first of additional products.

HealTech

Photo Credit:

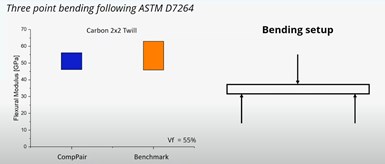

"With our technology, a repair agent is incorporated in the composite material," says CompPair CEO Amaël Cohades. “Cracks in the resin can be repaired on site in little time by heating the material to moderate temperature. The heating process activates the repair agent, and the damaged part quickly heals, without any change to the original properties.” This technology can reportedly be applied to all types of structures, extending their lifespan at least threefold. “The material’s properties and initial crack resistance are the same as those of traditional composites,” says Cohades. “What’s more, the technology is compatible with current manufacturing processes, so production facilities do not need to be retooled.”

CompPair sees its technology as beneficial for any composites application suffering from the damage it can repair. “The cost of maintaining the world's wind turbines alone is estimated at 13 billion Swiss francs in 2020,” says Cohades. “Our technology could also be applied to many parts that we don't bother to repair at present, like bikes and car bumpers.” One limitation is that the material doesn't heal if the impact breaks the fibers. However, repairing the matrix allows to recuperate most of the lost strength, even with some fibers broken, by recuperating the load transfer between plies; since the resin is always damaged first, this heat-based self-healing system would still work in the majority of cases.

“I am fascinated by CompPair’s technology and strongly believe in its market potential,” says Christian Fischer. “CompPair perfectly fits with my ambition to work with innovative tech companies that will have a positive impact on our future. I believe that I will be able to support the team in their exciting ventures thanks to my solid composites and entrepreneurship experience, and corresponding industry network.”

“CompPair’s technology and innovation answers to a real market need and I have strong confidence in my investment in the company," says investor and board member, Thomas Rauber of the StartAngels Network and CEO of TR Invest SA.

Launched in 2020, CompPair has been very active in the European Startup ecosystem. It was selected by Space4Impact as the Startup of the year 2020 and CompPair’s pre-impregnated textiles received the Solar Impulse Foundation Label in 2020. CompPair was a finalist in the Hello Tomorrow Global challenge in the aeronautics track, the JEC Startup booster 2020-2021 and the Swiss Technology Award at the Switzerland Innovation Forum. The company is listed as one of the top 40 best high-tech startups in Europe and in the world’s top five self-healing materials startups.

Related Content

Composites end markets: New space (2025)

Composite materials — with their unmatched strength-to-weight ratio, durability in extreme environments and design versatility — are at the heart of innovations in satellites, propulsion systems and lunar exploration vehicles, propelling the space economy toward a $1.8 trillion future.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MorePlant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

Read MoreTCR Composites introduces TR1116 snap-cure epoxy prepreg resin system

Designed for press-cure applications, the resin system is highlighted for its snap-cure capability and tailored properties.

Read MoreRead Next

New research on self-healing composites

Researchers have developed a method of allowing composites to self-heal cracks at temperatures well below freezing.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read More