Cevotec fiber patch placement improves storage efficiency of composite tanks

Cevotec’s solution is to apply carbon fiber patches to the dome areas of Type IV pressure vessels, which reportedly yields 15% in material, weight and cost savings.

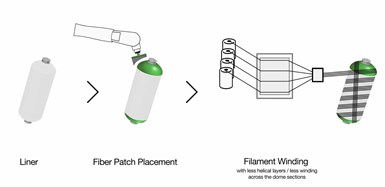

Cevotec fiber patch placement process for composite tanks. All photo credit: Cevotec

(Unterhaching, Germany) reports that it has developed an industrial solution to improve the storage efficiency of Type IV composite tanks in hydrogen-powered electric vehicles (EVs), reducing the amount of carbon fibers consumed by up to 15% while maintaining equivalent mechanical properties.

Cevotec’s solution is to apply carbon fiber patches in the tank’s dome areas, thereby replacing the high-angle helical layers (HAHL) in a typical filament winding pattern. Reinforcing a tank’s dome area with its fiber patch placement (FPP) technology reportedly yields 15% in material, weight and cost savings, and shortens total manufacturing time by 20%. By using FPP dome reinforcements, Cevotec says that manufacturers need less material in the subsequent filament winding process.

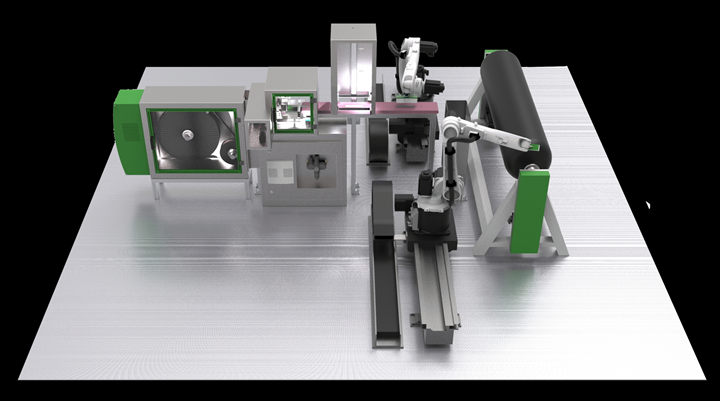

Cevotec’s fully automated, quality-controlled SAMBA FPP system first places the reinforcing fiber patches at the dome area directly on a standard liner. Then the patched liners are transferred over to the filament winding process; SAMBA requires no additional post-processing. The winding process is then adjusted to leave out the HAHL layers, for a faster, less material-intensive process, increasing overall line capacity for tanks, which further improves ROI and production economics

Related Content

-

Plant tour: Collins Aerospace, Riverside, Calif., U.S. and Almere, Netherlands

Composite Tier 1’s long history, acquisition of stamped parts pioneer Dutch Thermoplastic Components, advances roadmap for growth in thermoplastic composite parts.

-

Development of a composite liquid hydrogen tank for commercial aircraft

Netherlands consortium advances cryogenic composites testing, tank designs and manufacturing including AFP, hybrid winding, welding of tank components and integrated SHM and H2 sensors for demonstrators in 2025.

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.