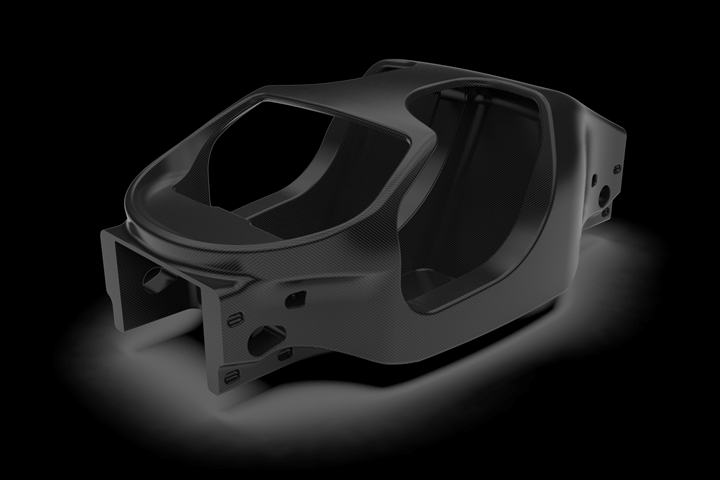

Carbon fiber prepreg monocoque masterclass launches September 15

First out of two live session masterclasses offered under The Native Lab’s Composite Materials training course is taking place Sept. 15 at 6 p.m. CET (12 p.m. EST).

Photo Credit: The Native Lab

In July 2022, The Native Lab (TNL, Madrid, Spain), Managing Composites’ training division, announced the addition of online sessions to its self-paced Composite Materials training course (learn more). One out of two of these online live sessions, a masterclass on manufacturing a carbon fiber prepreg monocoque, is taking place Thursday, Sept. 15, 2022 at 6 p.m. CET (12 p.m. EST).

Together, participants and the primary course trainer — Eneko Angulo, now chief operations officer (COO) of Managing Composites — will learn how to manufacture a carbon fiber prepreg monocoque, taking into account things like cosmetics, overlaps, width of roll, B-surface and sandwich construction. Angulo has previous experience from McLaren Automotive (Woking, U.K.) and Koenigsegg Automotive AB (Ängelholm, Sweden).

More than 100 people have already joined the composite materials course and will be joining the masterclass. By enrolling now participants will have access to this live session as well as all course materials. For more information .

Also learn more about a new course offered on monocoque structural analysis here.

Related Content

-

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

-

A different Ox-Ox prepreg for faster, more affordable CMC options

Isovolta has developed silica fiber/alumina CERAPREG to enable ceramic matrix composite parts with long-duration service at 900°C and handling similar to epoxy prepreg, dielectric performance similar to quartz.

-

Reducing accidental separator inclusion in prepreg layup

ST Engineering MRAS discusses the importance of addressing human factors to reduce separator inclusion in bonded structures.