Airtech 3D-printed resins deliver composite tooling for competitive motorsport vehicles

BBi Autosport joins with Airtech Advanced Materials Group to develop high-performance carbon fiber body panels for its Porsche race cars using Dahltram resins and Print-Tech services.

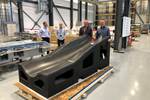

Photo Credit: BBi Motorsport

(Huntington Beach, Calif., U.S.) is returning to Pikes Peak, Colorado, for the 99th running of the Pikes Peak International Hillclimb on June 27, 2021. Known as “The Race to the Clouds,” the automobile hill climb is regarded as one of the most famous and arduous racing events globally. For this year’s 2021 effort, BBi says it is bringing three Porsche race cars, all of which make extensive use of carbon fiber composites and 3D-printing technologies.

The high-performance vehicles’ carbon fiber composite body panels were produced using 3D-printed mold tooling manufactured by BBi technical partner, Airtech Advanced Materials Group (Huntington Beach, Calif., U.S.), as well as Airtech’s Dahltram range of resins and Print-Tech in-house tooling 3D print service. Motorsports programs require rapid development cycles, BBi Autosport says, and with Print-Tech, molds are able to be produced much more quickly. This advantage further enables aerodynamic development and part manufacturing to be completed in weeks, rather than months.

Airtech’s Dahltram range of resins have been made distinctly suitable for multiple print platforms, providing production flexibility with end use material approvals. Continuous thermal cycle testing, pressure leak testing, laser surface scanning and contact material testing have generated data supporting more than 250 autoclave cycles, Airtech says, without degradation of the Dahltram manufactured tooling.

Airtech’s retains Dahltram additive manufacturing resins and Print-Tech large-scale 3D-printed tool manufacturing capabilities in the U.S. and Europe.

Related Content

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

-

Cutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

-

Bladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.