Ginger Gardiner Senior Technical Editor

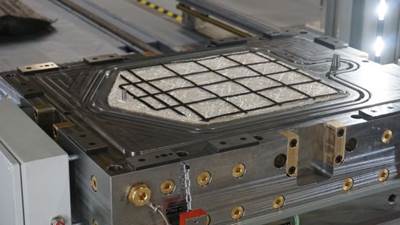

iComposite 4.0 — cutting composites cost by 50%

An intelligent, integrated process using 3D fiber spraying, inline inspections/simulation and embedded RFID chips to cut scrap and rejections for structural HP-RTM epoxy parts.

Read MoreConsolidating thermoplastic composite aerostructures in place, Part 2

Thermoplastic composite structures could eliminate the autoclave and fasteners, but will a one- or two-step process prevail?

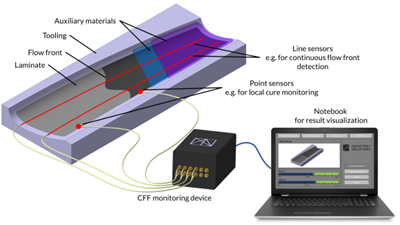

Read MoreSensors for monitoring resin infusion flow front and cure

InFactory Solutions commercializes technology to provide real-time resin impregnation and cure data across composite parts for zero-defect, intelligent process chains.

Read MoreAirborne, Siemens and SABIC partner to mass produce thermoplastic composites

Flexible, automated production lines, featuring radically low conversion costs, aimed at millions of parts/yr — CW’s interview with all three companies.

WatchCarbon Fibre Preforms for low-cost and zero waste

Chopped fiber preforms in seconds, 1200°C burn resistance for hours, low-cost CFRP to replace metals

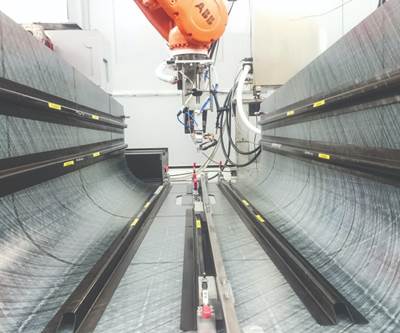

WatchFiber Patch Placement at scale

SAMBA automated cells now offered in Step, Pro and Scale models, for 3D preforming dry fiber and prepreg at rates up to 15-100 kg/hr.

WatchShapeTex preforms successful in automotive parts

Shape Machining Ltd. has demonstrated lightweight composite parts in automotive development program.

Read MoreKordsa pursues composites R&D

Turkish reinforcements supplier posts record number of patents and inventions, with over 25% from its Composites Technologies Center of Excellence.

Read MoreSGL Group optimizes supply chain for composites

SGL’s takeover of former BENTELER and BMW JVs, plus sale of Kumpers JV, consolidates the company’s CF activities while it broadens its composites technology portfolio.

Read MoreConsolidating thermoplastic composite aerostructures in place, Part 1

After more than 30 years of development, in-situ consolidation is nearing its promise to eliminate fasteners and the autoclave, and enable an integrated, multifunctional airframe.

Read MoreThermoplastic composite demonstrators — EU roadmap for future airframes

There is a TPC development roadmap in Europe, supported by Airbus and a variety of aerospace consortia, and involving almost every major aerostructures supplier in Europe.

Watch3D-printed composite wind blades and aircraft, closer than you think

Orbital Composites’ patented coaxial extrusion process is investigated at Airbus subsidiary CTC GmbH Stade and spins off advances in speed, scale, materials and multifunctionality as it aims for very large structures.

Read More