CW Blog

CAMX 2017 preview: Autonational

AUTONATIONAL Composites BV (Ijlst, The Netherlands) is featuring its solutions for filament winding for its customers from all over the world.

Read MoreCAMX 2017 preview: Armacell

Armacell Benelux SA is showcasing its ArmaFORM PET product family.

Read MorePlant Tour: BENTELER SGL, Ort im Innkreis, Austria

High-volume CFRP structures pioneer makes industrialization and multimaterial assembly look easy.

Read MoreComposite cases fuel commercial space venture

Launch vehicle supplier Orbital ATK is looking to break into the burgeoning commercial space market with a rocket motor that features an all-carbon fiber case.

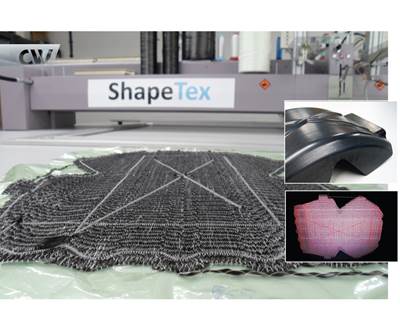

Read MorePreforming goes industrial: Part 2

Automated preforming isn’t only for 2D and 2.5D parts. Innovators are taking successful aim at building 3D preforms at production speeds.

Read MoreSMC: Old dog, more tricks

In the sheet molding compound renaissance, the advent of new resins and compounds are broadening the definition and application of this versatile family of composites.

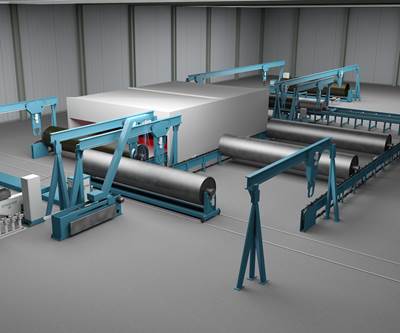

Read MoreCenter for mass production of lightweight composites

German R&D center brings together 8 institutes and more than 80 companies from 120 countries to help industrialize composite parts production.

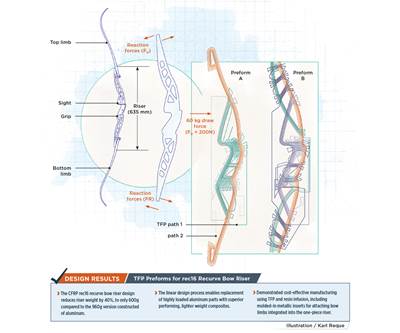

WatchVariable-axial composites open path to lighter composite structures

CFRP recurve bow riser demonstrates design and manufacturing approach with potential to cut weight vs. aluminum by 50-75% while increasing strength and stiffness.

Read MoreFiber-metal laminates in the spotlight

Interest in FMLs is growing again as aeroengineers search for lightweight solutions adaptable to new narrowbody commercial aircraft.

Read MoreEpisode 5: Greg Mark, Markforged

Greg Mark, founder and CEO of Markforged, discusses his journey of working with composites in additive manufacturing.

ListenThe Grenfell Tower Fire - Let's make sure our architectural composites meet the codes

The devastating and deadly fire in a residential high-rise tower in London on June 14 did NOT involve composite materials as defined by ÂÌñÏ×ÆÞ magazine, our readers and most composite suppliers.

Read MoreSoftware shortens design path to longboard

Materials information program helps optimize materials selection.

Read More