The Grenfell Tower Fire - Let's make sure our architectural composites meet the codes

The devastating and deadly fire in a residential high-rise tower in London on June 14 did NOT involve composite materials as defined by ÂÌñÏ×ÆÞ magazine, our readers and most composite suppliers.

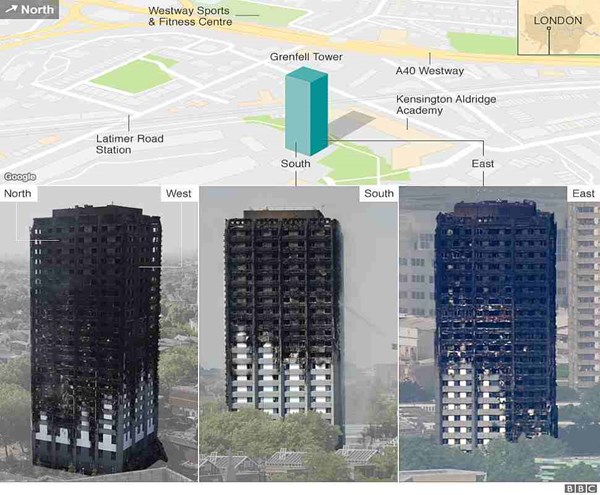

Photos from the BBC show the extent of the fire damage in the Grenfell Tower (source: BBC News)

First, the devastating and deadly fire in a residential high-rise tower in London on June 14 did NOT involve composite materials as defined by ÂÌñÏ×ÆÞ magazine, our readers and most composite suppliers. The Reynobond PE cladding panels that were involved in the fire, part of a “rainscreen” exterior installation (here’s a link to one of my articles from a few years back, where raincreens are discussed: http://www.compositesworld.com/articles/the-building-envelope-betting-on-the-big-time), were made of thin aluminum skins over a thermoplastic core, and manufactured by Arconic (New York, NY, US, the successor company to Alcoa Inc., which split into two entities in 2016 — Alcoa Corp. retains alumina, aluminum and bauxite production operations). Media reports say that a refrigerator placed close to an exterior wall might have been the fire source, and that the rainscreen air gap designed to keep rain out of the building instead acted as a chimney, funneling the flames that burned the decorative panels as well as the underlying Celotex polyisocyanurate (PIR) rigid thermal insulation. This is the latest in a succession of external cladding fires over the past 10 years, and there is good evidence that such cladding, if not properly fire tested, can spread fire externally on a building, both on the external cladding surface and within the cladding assembly, says Dr. Nicholas Dempsey, professor at Worcester Polytechnic Institute’s (Worcester, MA, US) Fire Protection Engineering department.

There are two big issues here, in my opinion. First, this cladding laminate obviously wasn’t fire retardant, and published reports including a New York Times article from June 24th (here’s the link: ) say it was installed inappropriately — that the aluminum laminates only “resisted” ignition, and in Britain regulators apparently did not require fire testing to evaluate flammability in as-installed conditions. US regulators don’t allow these and similar rainscreen cladding systems involving plastic above the height of a fireman’s ladder, about 4 stories, unless they pass the National Fire Protection Assn.’s (NFPA) 285 full-scale assembly test, as well as the ASTM E84 Standard Test Method for Surface Burning Characteristics of Building Materials and other tests, for compliance with US building codes.

The second issue is that the composites industry, which has the ability to provide façade materials compliant with International Code Council (ICC) International Building Code (IBC), Chapter 26 (Plastic) (we’ve written about one, the San Francisco Museum of Modern Art: http://www.compositesworld.com/articles/sfmoma-faade-advancing-the-art-of-high-rise-frp), has a responsibility to communicate with customers exactly what their materials can do in actual, as-installed situations, using actual fabrication methods — how fire resistant they are, the codes they comply with, the tests they can pass. And, suppliers should clearly label products with this information, in accordance with the building codes, so that architects and builders know with certainty what they’re getting, says architectural composites champion Bill Kreysler of Kreysler & Associates Inc.

Britain has, according to a June 25 article in The Guardian (), 60 more housing high-rises with similar cladding. Architectural composites supplier Acell Industries Ltd. (Dublin, Ireland), about which we’ve written (http://www.compositesworld.com/news/smc-cladding-panels-preserve-pre-1919-building-aesthetics, for example) says it has a solution for this issue: for an affected building, remove the cladding, remove the underlying insulation, and wrap the insulation with its fire-resistant phenolic AMC (Acell molding compound) foam panels, which the company claims would protect the insulation from any fire in the cladding.

There are undoubtedly other fixes that our industry could supply. No matter how this plays out, we certainly don’t want to see a disaster of the Grenfell Tower scale happening in a building involving fiber-reinforced composites.

Related Content

Composite materials, design enable challenging Corvette exterior components

General Motors and partners Premix-Hadlock and Albar cite creative engineering and a move toward pigmented sheet molding compound (SMC) to produce cosmetic components that met strict thermal requirements.

Read MoreIDI Composites opens new global headquarters, manufacturing and technology center

The Noblesville, Indiana, facility includes SMC and BMC manufacturing, an R&D center and the company’s corporate headquarters.

Read MoreNational Composites announces partners with compression toolmaker Laval

The new alliance will broaden National Composites’ capabilities in SMC and BMC and tooling, while providing customers with comprehensive solutions, from initial design to final delivery.

Read MoreMatrix Composite highlights carbon fiber SMC prepreg Quantum-ESC

Prepreg produced by LyondellBasell features high flow, rapid tool loading capabilities.

Read MoreRead Next

Ultrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read More