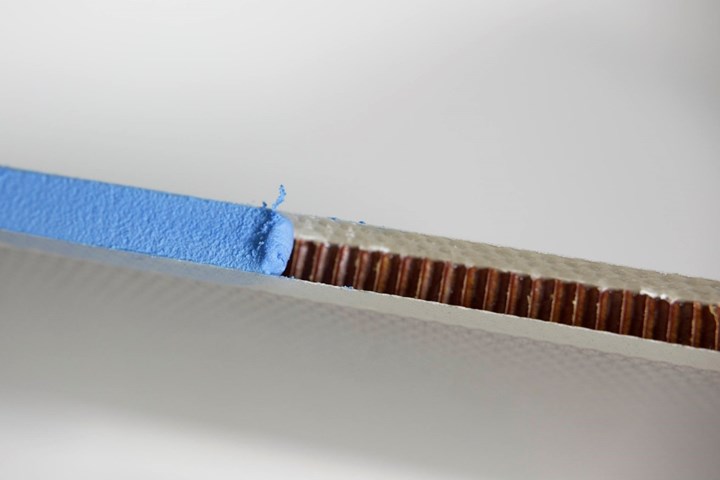

L&L Reinforce L-9060: A new approach to fill and reinforce aerospace sandwich panels

L&L Products brings a new approach to fill and reinforce aerospace sandwich panels with L&L Reinforce L-9060. (Sponsored)

- Ultralight density epoxy-based syntactic, 0.55kg

- FST compliant to FAR / JAR 25.853

L&L Products has launched a new FST aircraft interior edge and core filler compound. L&L Reinforce L-9060 brings a new approach to fill and reinforce aerospace interior sandwich panels by providing a solution to improve the traditionally manual process of other two-component honeycomb panel reinforcements.

Product benefits include:

- Process – Easy to use and clean with no hand mixing, accurate mixing of two components, no waste, and suitable for automatic metering pumps. The equipment to process the cartridge is a standard 400ml manual or pneumatic gun.

- Lightweight – Ultralightweight density (0.55kg) to help reduce the overall weight of aircrafts, therefore reducing CO2 emissions and fuel consumption.

- FST – compliant with FAR / JAR 25.853, which reinforces safety on board and reduces certification cost.

- Safety – contains no Carcinogenic, Mutagenic, or Reprotoxic (CMR) substances, is REACH compliant, and contains no odor.

For more information on this and other L&L Products, visit and follow them online on , and LinkedIn.