Increasing the composite stack: Co-molding of dissimilar materials

This demo introduces the concept of co-molding with thermoset composites to improve the final part performance. (Sponsored)

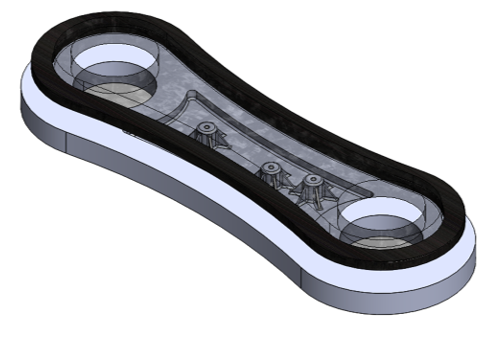

This demo introduces the concept of co-molding with thermoset composites to improve the final part performance. This overview is for those who are unfamiliar with thermoset materials and their molding processes. During this presentation, LyondellBasell will review the functional elements of composite materials and defining the types of challenges that co-molding can solve based on their size relative to the finished part. They will also discuss the use of metal inserts, including design concerns and material selection, along with more advanced concepts in the co-molding of different molding compounds and the use of additional filler bodies.

For more information on this and other LyondellBasell products, visit and follow them online on , Twitter, and LinkedIn.

Related Content

-

Plant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

-

Norco GFRP molds meet high-quality cast concrete beam production needs

A project with P&M successfully achieved manufacture of six 20-meter-long architectural beams for an R&D facility with near-seamless surfaces and on a tight production schedule.

-

Optimized rib-reinforced hollow composites via printed molds

Addyx topology optimization and water-soluble mandrel enables simultaneous rib and skin layup for one-shot, high-strength, lightweight structures.