High-speed 3D printing with fiber reinforcement

Italy-based CMS has partnered with Fraunhofer IWU to develop a high-speed, extrusion-based process for the 3D printing of fiber-reinforced thermoplastic parts. Video included.

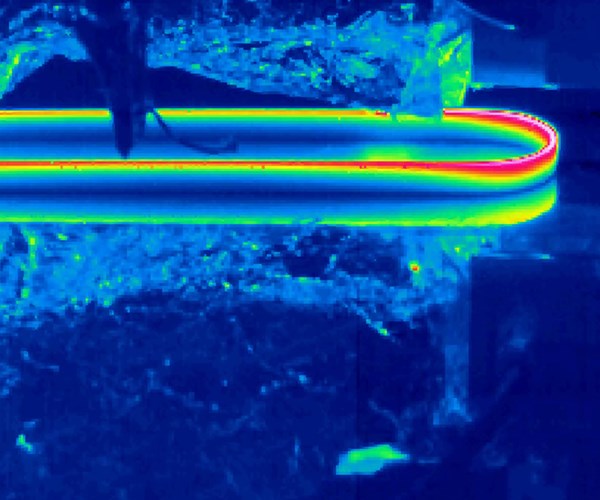

Heat map of CMS Kreator laying down fiber-reinforced thermoplastic resin.

and report that they are working on an R&D partnership focused on the development of a new hybrid system for high-speed 3D printing and machining of thermoplastic composite parts.

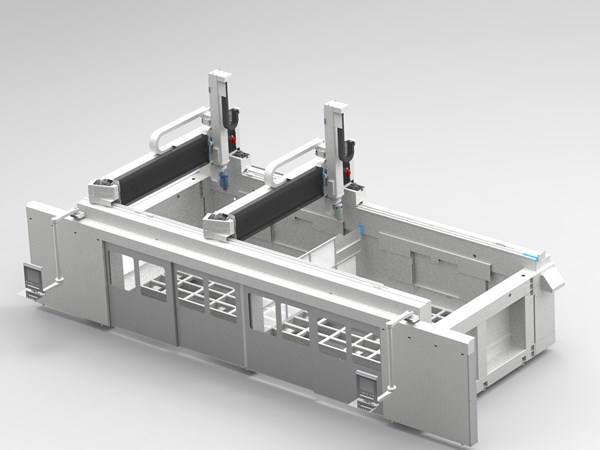

The new system, named CMS Kreator, will be available in several configurations and sizes, to cover a variety of industrial needs, mainly targeted toward the manufacture of prototypes and special parts. The range of materials used by CMS Kreator includes ABS, PA and high-performance polymers, mixed with short fiber carbon fiber and glass fiber to provide 40% fiber content.

Potential applications include mockups and jigs, as well as tools and molds able to withstand the cure temperatures. All materials used by the system are granulate, like that currently used in injection molding, are readily available on the market at a much lower cost when compared to the cost of standard 3D printing materials.

The process is extrusion-based and designed to lay down thin strands of material quickly (eight times faster than standard FDM processes) and immediately cooled, for the building of "birdbone" and similar structures.

The programming software tools are based on solutions available on the market. CMS also can provide the system with a 5-axis milling unit for finishing, and with a fiber placement unit for the fabrication of thermoset carbon fiber composites.

CMS Kreator.

Related Content

-

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

-

Bladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

-

Low-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.