Digital Demo: Aerospace Carbon Fiber Infusion

Learn how this process combined with carbon fiber can offer the manufacturer the benefits of increased strength and the ability to make a lighter-weight part.

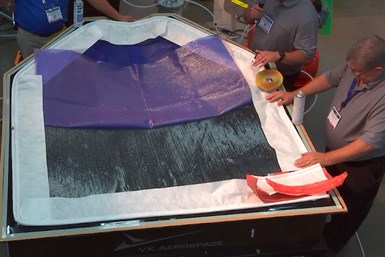

During their annual CAMX demonstration in 2021, Composites One produced a UAV wingskin part using carbon fiber and vacuum infusion. Learn how this process combined with carbon fiber can offer the manufacturer the benefits of increased strength and the ability to make a lighter-weight part.

Composites One also highlights their brand Aerovac, a manufacturer of process materials for vacuum infusion.

Related Content

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

-

Plant tour: Aernnova Composites, Toledo and Illescas, Spain

RTM and ATL/AFP high-rate production sites feature this composites and engineering leader’s continued push for excellence and innovation for future airframes.