Laser NDT, DIC systems demonstrate optimized noncontact composites inspection

CAMX 2024: Dantec Dynamics is presenting three of its laser shearography NDT and DIC devices, geared toward reliable measurement results.

Share

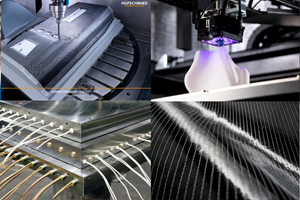

Dantec Dynamics (Holtsville, N.Y., U.S.) is exhibiting its laser shearography nondestructive testing (NDT) and digital image correlation (DIC) devices. Presented products will include the company’s FlawHunter NDT system, FlawExplorer and MulticamDIC.

Laser shearography NDT is an optical, NDT measurement technique that is used for the inspection of composite materials, including laminates, honeycombs, sandwiches, bonded and coated components, rubber, spray foams and sealants. Laser shearography provides high inspection rates (i.e., m2/sec), low sample preparation times and simple automatability.

DIC is also an optical, noncontact measurement technique, though it is used to determine the shape (contour), displacement and strain for experimental solid mechanic applications in materials testing. The technique can also be used to determine kinematic quantities of discrete points, such as rotations, velocities and accelerations.

On display is the FlawHunter NDT system, an integrated NDT inspection device equipped with a high-resolution laser shearography sensor with a vacuum (partial) excitation system. It is said to be ergonomic and easy to use, with a workflow-oriented GUI display and left/right-hand button control. Regardless of the application, the FlawHunter provides reliable and resolute measurement results for in-field (service) NDT and quality control (post-production) operations, according to the company.

The FlawExplorer is a laser shearography NDT sensor designed to be used for post-production quality control applications or in-field (in-service) component inspections. Depending on the application, the sensor can be configured with thermal or vacuum (partial) excitation systems and may also be automated. It incorporates phase-shifting technology intended to deliver accurate and reliable measurement results through clear and sharp imaging with sub-micrometer displacement resolution.

The MulticamDIC is a combined, stereo-rig array, DIC measurement system consisting of four or more (up to 16), USB3 or GigE cameras. This application-specific measurement system gives testing engineers the ability to perform large-scale and complex (contoured) surface testing of sub-(components) and structures.

The FlawExplorer Laser Shearography NDT and DIC systems are being used together to demonstrate an internal pressure test of a composite-overwrapped pressure vessel (COPV).

Related Content

-

Controlled polymer ablation enables stronger composite bonds

CAMX 2025: Plasma Bound’s surface pretreatment technology using CPA cleanly and effectively energizes similar and dissimilar surfaces to enhance bonding and joining.

-

Highly tunable, woven lattice reinforcements target automotive structures

CAMX 2023: Startup Weav3D will be demonstrating its two collaborative automotive demonstrator parts and present two conference papers.

-

VIDEO: Recycling and machining carbon fiber scraps

Elevated Materials has partnered with ‪Toray Composite Materials America, Inc. to collect and upcycle reclaimed carbon fiber scraps into large billet laminates, which can then be cut into various parts using CNC mills.

Related Content

Controlled polymer ablation enables stronger composite bonds

CAMX 2025: Plasma Bound’s surface pretreatment technology using CPA cleanly and effectively energizes similar and dissimilar surfaces to enhance bonding and joining.

Read MoreHighly tunable, woven lattice reinforcements target automotive structures

CAMX 2023: Startup Weav3D will be demonstrating its two collaborative automotive demonstrator parts and present two conference papers.

Read MoreVIDEO: Recycling and machining carbon fiber scraps

Elevated Materials has partnered with ‪Toray Composite Materials America, Inc. to collect and upcycle reclaimed carbon fiber scraps into large billet laminates, which can then be cut into various parts using CNC mills.

Read MoreCAMX 2023 exhibit preview compilation, Part 2

Part 2 continues to showcase the materials, services, machinery, live demonstrations and other innovations presented by CAMX 2023 exhibitors.

Read MoreRead Next

Testia releases multi-method acquisition system for NDT inspection methods

Multi-method UE1 Box, phased array U32 Box and SKD architecture improve activity efficiency and meets technical specifications on a flexible, cost-effective platform.

Read MoreAutomated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read More