Digital workflows optimize material yields, design and productivity

CAMX 2024: TruComposites and Evolv GMP digital manufacturing solutions by Magestic Technologies drive efficiencies and precision across composites manufacturing disciplines.

Share

TruComposite nesting capabilities. Sourc | Magestic Technologies

(Pearl River, N.Y., U.S.) showcases the latest updates to to its digital manufacturing solutions, Evolv GMP and TruComposites, which elevate material yields through improved nesting processes and optimize entire manufacturing workflows like hand layup and AFP/ATL with advanced AI and genetic algorithm capabilities.

Evolv GMP is designed to transform operations across various industries, including aerospace, energy, transportation and automotive. According to the company, it ensures versatility and effectiveness in diverse industrial settings. In addition, TruComposites is a comprehensive software solution tailored specifically for composites materials manufacturing.

Magestic’s goals are to enhance efficiencies and precision across composites manufacturing disciplines. The company’s available technologies achieve this through:

- Customized manufacturing solutions: Magestic software solutions offer flexibility and reliability. With streamlined integration, they are designed to adapt to diverse production environments for complex manufacturing needs.

- Generative AI and genetic algorithms: These updates increase nesting yields, reduce material waste and improve production efficiency. The technologies are engineered for high-stress and high-performance applications, maximizing resource utilization and minimizing costs.

- All-in-one materials platform: Magestic Technologies’ TruComposites platform enables multi-discipline performance in processes like hand layup, AFP/ATL, kinematics simulation, composites design and more.

Attendees have the opportunity to test the latest builds of the company’s flagship software, Evolv GMP, exploring its various features, including Magestic’s AI-driven process optimization and genetic algorithm enhancements. Additionally, TruComposites is available for viewing firsthand.

Related Content

-

Collier Aerospace HyperX optimizes X-59 composite nose cone

Swift Engineering relied on the CAE software’s structural sizing, analysis and test validation capabilities to deliver flight hardware for NASA’s supersonic QueSST aircraft early, under budget and with 25% weight savings.

-

NCC leads composites manufacturing phase of eXtra wing demonstrator

Key structural elements for a 6-meter section of the Airbus biomimetic wing were undertaken by NCC engineering specialists to produce 28 one-off flying parts.

-

Testing to support composite bolted joint analysis

An overview of ASTM Standard Guide D8509, and its coupon-level mechanical testing of design properties for analyzing composite bolted joints.

Related Content

Collier Aerospace HyperX optimizes X-59 composite nose cone

Swift Engineering relied on the CAE software’s structural sizing, analysis and test validation capabilities to deliver flight hardware for NASA’s supersonic QueSST aircraft early, under budget and with 25% weight savings.

Read MoreNCC leads composites manufacturing phase of eXtra wing demonstrator

Key structural elements for a 6-meter section of the Airbus biomimetic wing were undertaken by NCC engineering specialists to produce 28 one-off flying parts.

Read MoreTesting to support composite bolted joint analysis

An overview of ASTM Standard Guide D8509, and its coupon-level mechanical testing of design properties for analyzing composite bolted joints.

Read MoreGenerative Orthoses project to reshape orthopedic care

CRP Technology, MHOX and Istituto Ortopedico Rizzoli, one of the winners of the WORTH Partnership Project II, have developed bespoke orthoses using generative design, Windform GT fiberglass materials and PBF.

Read MoreRead Next

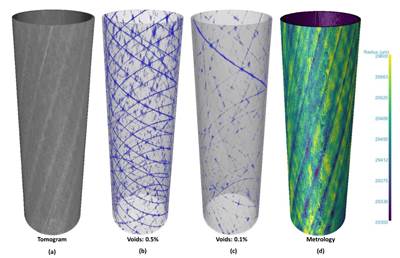

Multi-scale 3D CT imaging enables digital twinning, high-fidelity simulation of composite structures

Computed tomography (CT) provides highly accurate 3D analysis of internal microstructure, performance simulation of carbon fiber/PEEK satellite strut.

Read MoreJetcam releases JOC 4 nesting software update

JOC 4 is the first of several major product releases this year that continue on the path of automation, integration and simplifying the performance of complex operations.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read More