Collier Aerospace HyperX optimizes X-59 composite nose cone

Swift Engineering relied on the CAE software’s structural sizing, analysis and test validation capabilities to deliver flight hardware for NASA’s supersonic QueSST aircraft early, under budget and with 25% weight savings.

Collier Aerospace’s design and analysis software was chosen by Swift Engineering Inc., for structural sizing, analysis and test validation of the X-59 aircraft’s nose cone. Sources (All Images) | Lockheed Martin/NASA

Collier Aerospace Corp. (Newport News, Va., U.S.), developer of the HyperX computer-aided engineering (CAE) solution, announces that its design and analysis software was chosen by Swift Engineering Inc. (San Clemente, Calif., U.S.), for structural sizing, analysis and test validation of the low-boom X-59 aircraft’s carbon fiber-reinforced polymer (CFRP) nose cone.

This experimental aircraft from (Palmdale, Calif., U.S.) is part of NASA’s Quiet SuperSonic Technology (QueSST) mission to quiet loud sonic booms (CW reported on the X-59 in this 2022 article). Swift Engineering was contracted to build and perform structural analysis and certification testing for the X-59’s 35-foot-long nose cone, designed to control aerodynamic pressure waves (shock waves) that form at the sharp nose tip during supersonic flight, resulting in quieter sonic booms.

Collier Aerospace says its software enabled Swift Engineering to remove mass that reduced the nose cone’s weight by more than 25% while maintaining dimensional stability; evaluate the design for a wide range of load cases; and provide detailed stress reporting to support part release and fabrication. The company also used the software to perform detailed analyses, supporting structural testing substantiation of the structural design.

“Collier Aerospace software played a critical role throughout this high-visibility project to design, engineer and build the X-59 nose structure,” says Bill Giannetti, technical consultant to Swift Engineering. “At the outset, when the team from Skunk Works explained how important lightweighting was, I had so much confidence in the software that I was convinced we would remove 100 pounds from the nose cone. However, we surpassed that goal by achieving a significant weight savings of over 25%.

“We were able to iterate the structural sizing software with our finite element analysis solver, which enabled weight reduction through structural optimization and rapid load path convergence,” continues Giannetti. “Once the system was set up, we could literally watch the mass come out of the nose structure, while meeting all the traditional aerospace failure criteria simultaneously.”

X-59 supersonic aircraft.

To lower the weight of the approximately 400-pound preliminary design, which specified graphite/epoxy composite and a honeycomb-core sandwich structure, Swift Engineering’s team removed unnecessary plies, simultaneously optimizing the structure for stress and stability. The Collier Aerospace software enabled the team to quickly evaluate design alternatives by considering tradeoffs in ply-layup schedules and core panel and edge band thicknesses, and then rapidly evaluate the change to the section stiffness and deflection.

Swift Engineering reports having used the full capabilities of the Collier Aerospace software for this aircraft nose structure, extending beyond preliminary sizing and optimization to include conducting detailed laminate strength analysis using design allowables derived from testing. The software enabled the company to deliver the nose cone ahead of schedule and under budget.

HyperX software automates stress analysis and design. It performs rapid structural sizing to all load cases, lightweighting and margin writing. The software helps ensure the producibility of a composite part by creating a design that is optimized for manufacturability. It reduces schedule time by speeding up the engineering cycle and shortening the U.S. Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) certification processes.

The goal of the X-59 aircraft, which is expected to make its first flight in 2025, is to help establish an acceptable noise standard for commercial supersonic flights over land, potentially resulting in U.S. and international regulators lifting a five-decade-long ban that was imposed due to loud sonic booms. Thanks to its distinctive geometry, particularly the elongated nose cone, the X-59 is expected to generate a barely audible thump rather than a boom, reducing noise impacts.

“We’re grateful that our software helped Swift Engineering achieve success with the X-59 nose cone and met the high expectations of Lockheed Martin Skunk Works,” says James Ainsworth, vice president, engineering services, Collier Aerospace. “The high level of credibility that our solution has earned, and its powerful sizing and analytical capabilities, were key factors in Swift’s decision to choose our software. We’re looking forward to the X-59’s first flight.”

Related Content

Troubleshooting thermoplastic composite stamp forming

Understand the basic science of TPC stamp forming, a manufacturing process steadily gaining momentum in aerospace and mobility applications thanks to its rapid forming, short cycle times and automated methods.

Read MoreCarbon fiber/flax landing gear achieves 54% weight reduction via tailored layup optimization

Fuko’s Biogear showcases how strategic composite material distribution and natural fiber damping properties can lightweight and enhance critical aerospace structure performance.

Read MoreMulti-scale 3D CT imaging enables digital twinning, high-fidelity simulation of composite structures

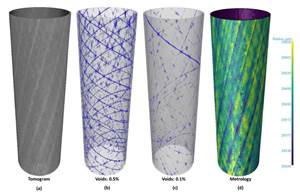

Computed tomography (CT) provides highly accurate 3D analysis of internal microstructure, performance simulation of carbon fiber/PEEK satellite strut.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreRead Next

Collier's HyperSizer software used for Dream Chaser design and analysis

The Dream Chaser spacecraft team is reviewing flight performance data and refining the vehicle’s design adaptations using the HyperSizer software.

Read MoreDigital design, multi-material structures enable a quieter supersonic NASA X-plane

NASA’s composites-intensive X-59 QueSST experimental aircraft is set for its first flight by the end of 2022, after nine years of design, manufacture, assembly and testing by Lockheed Martin Skunk Works.

Read MoreLockheed Martin rolls out X-59 supersonic X-Plane

The composites-intensive aircraft demonstrator was highlighted at a rollout ceremony at Lockheed Martin Skunk Works, and will soon undergo extensive testing prior to first flight later this year.

Read More