Company R&D supports specialty resins, additives development

CAMX 2024: Interplastic highlights its range of specialty resin offerings, as well as its advancements in R&D producing gelcoats, colorants, bonding compounds, adhesives and putties.

Share

Interplastic Corp. (Covington, Ky., U.S.), a U.S.-owned and operated company offering a collective experience of 500 years, specializes in unsaturated polyester, vinyl ester and specialty resins. The company also produces gelcoats, colorants, bonding compounds, adhesives and putties under CoRezyn and Silmar brand names for the composites, cast polymer and solid surface industries. Its CoRezyn vinyl esters are said to be reliable for high-performance and high-corrosion applications, designed to be used across marine, transportation and construction industries. Silmar, its flagship brand for low-color (clear) resins, optimizes quality and consistency. As part of the IP Corp. family of companies, Interplastic partners with HK Research for other robust gelcoat manufacturing options.

The company has also expanded its manufacturing capabilities and invested in R&D. All of Interplastic’s manufacturing facilities and research labs maintain ISO 9001:2015 certification from ABS Quality Evaluations Inc., ensuring rigorous quality management practices and product refinement. The company also highlights its commitment to environmental responsibility, which is reflected in its ISO 14001:2015 registered environmental management systems.

Interplastic’s sales team is available to address inquiries and provide technical expertise.

Related Content

-

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

-

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

-

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Related Content

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

Read MoreWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MorePlant tour: Collins Aerospace, Riverside, Calif., U.S. and Almere, Netherlands

Composite Tier 1’s long history, acquisition of stamped parts pioneer Dutch Thermoplastic Components, advances roadmap for growth in thermoplastic composite parts.

Read MoreRead Next

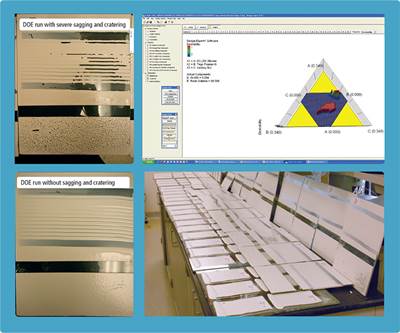

Cure for cratering: Gel coat perfected with design of experiments software

Resin manufacturer Interplastic Corp. – Thermoset Resins Div. (St. Paul, Minn.), a major gel coat producer, recently developed a new gel coat with the aid of Design-Expert design of experiments software from Stat-Ease Inc. (Minneapolis, Minn.).

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read More