Videos

National Composites Week: Sustainability

As we celebrate National Composites Week, here are just a few of the many ways the composites industry is working toward a sustainable world.

WatchIncreasing access to AFP

Addcomposites is democratizing composites manufacturing by leasing a low-cost toolhead that turns any robot into an automated fiber placement machine.

WatchCelebrate National Composites Week, August 26-30

2019 marks the inaugural year for National Composites Week, which celebrates the ways in which composites enable innovations in a wide range of industries.

WatchICON Aircraft produces 100th A5 sports aircraft

The carbon fiber composite fuselage and structures were produced at ICON’s 300,000-square-foot production facility in Tijuana, Mexico.

WatchAFRL, Boeing, Thermwood partner to develop low-cost, autoclave-capable tooling

The project is using Thermwood’s vertical, large-scale 3D printer to build a carbon fiber-reinforced demonstrator tool for an aircraft fuselage skin.

WatchEpisode 27: Ryan Olliges & Jaysen Harris, Elevated Materials

Elevated Materials’ CEO Ryan Olliges and CTO Jaysen Harris discuss the company’s mission and unique approach to keeping carbon fiber out of the landfill.

ListenFIBRESHIP demonstrates ship hull section built in fiber-reinforced composite

EU-funded project aims to replace steel in ships, reducing weight, fuel consumption and carbon emissions.

WatchCovestro steps up investments in thermoplastic composites

The company introduces a new R&D tape line and hybrid injection molding machines for new fiber and resin combinations.

WatchHighlights: Composites Convention 2019

Highlights from the Composites Convention 2019, June 12-13, in Stade, Germany, organized by CFK Valley e.V. and Carbon Composites e.V, and the German Aerospace Center’s 5th Colloquium on Production Technology, on May 15, in Augsburg.

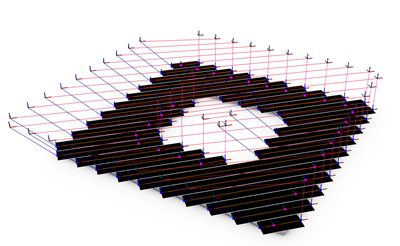

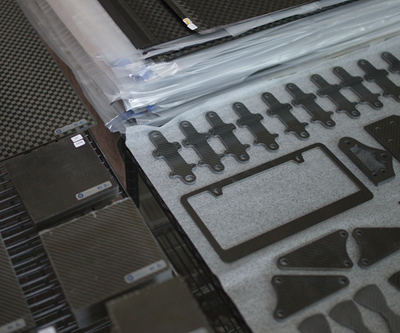

WatchAddcomposites introduces plug & play AFP/ATL for cost-effective composites manufacturing

New AFP-XS turns any robotic arm into an automated composites manufacturing system.

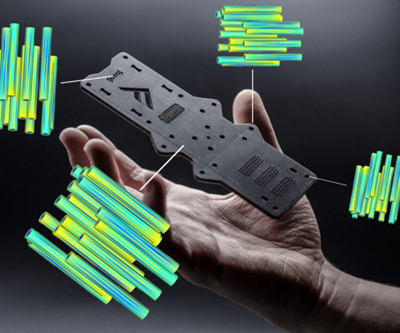

WatchMagnetic 3D printing the next generation of tailored composites

Fortify uses magnetic fields and digital light processing to produce tailored microstructures for high-resolution, 3D printed composite parts — and enables the next generation of multiscale, multifunctional composite metamaterials.

WatchFilament wound utility poles offer design flexibility

In Turkey, a utility pole manufacturer combines filament winding, automation, glass and carbon fiber composites to expand its product line.

Watch