Weaving

Editorial - 2/1/2005

This February issue of Composites Technology, our first of 2005, reflects the varied nature of the composites business these days. There is a lot going on, in every area you can imagine. Starting with a product as basic as mold release -- its been a concern of every manufacturer for as long as parts have been

Read MoreFiberglass multiaxials reinforce their market share

Technological and market forces feed growing use of multiaxial nonwoven fiberglass fabrics and spur diversified product offerings.

Read MoreMold release update

New products from mold release manufacturers emphasize ease of use and application flexibility.

Read MoreSmall-scale blade manufactured via bladder molding

High-compression bladder molding and modular tooling prove cost-effective for manufacture of small wind turbine rotor blades.

Read MoreSITE Manufacturing

SITE Manufacturing (Redding, Calif.) has taken knowledge acquired during more than 23 years of producing hi-tech carbon composite components, such as telescope housings (for Celestron, see story on p. 20), and applied it to the sport of paintball. "One year around Christmas, we decided we wanted to do something else,"

Read MoreComposites on the frontlines

Armored vehicle applications on the ground and in the air fuel a growing, evolving market forhigh-performance materials.

Read MoreCarbon fiber raises consumer performance index

Carbon bridges gap between large-volume sporting goods and aerospace to satisfy discriminating tastes in consumer and professional markets.

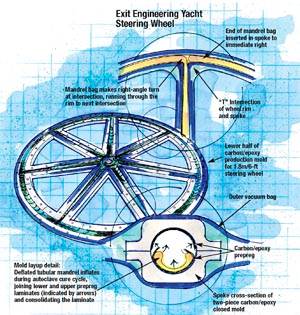

Read MoreOne-piece molded carbon steering wheel for yachts

Concurrent product and manufacturing system design creates lightweight, hollow spoked structure without joints.

Read MoreComposites Aboard High-Speed Trains

Greater demand for weight reduction and aerodynamics put railcar manufacturers on track to greater and more extensive use of composites.

Read MoreComposites Cut Costs Of Repairing Corrosion-Prone Systems

Composites materials and processing methods extend the useful life of noncomposite structures in industrial and infrastructure systems.

Read More