Trends

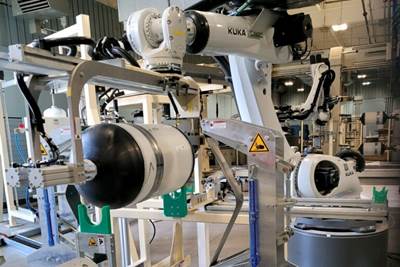

Automated filament winding system increases throughput, reduces manual labor for pressurized well tank production

For its new line of composite well water tanks, Amtrol worked with Roth Composite Machinery on an automated process for faster, more easily tracked production.

WatchBoeing reveals new Advanced Composite Fabrication Center

First of new purpose-built innovative defense factories based in Mesa, Ariz., U.S., will produce advanced composite components, leverage Industry 4.0 best practices from recent programs.

Read MoreNew initiatives launched to expand U.S. offshore wind energy

The White House announced a new goal of 15 GW floating offshore wind energy by 2035, and new R&D funding and programs.

Read MoreUniFORM: High-quality, high-complex EV battery enclosures at low cycle times, low tooling costs

Stellantis subsidiary CpK Interior Products Inc. recently completed a design challenge to prove out its vacuum-assisted wet compression molding process for CFRP battery trays.

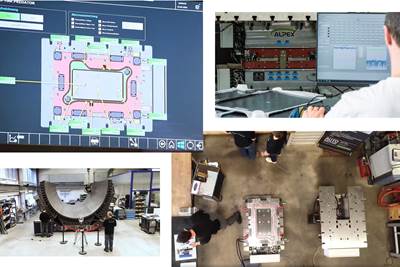

Read MoreDigitizing tools for composites production

Alpex Technologies focuses on industrialization, process and part intelligence and biocomposites in its next generation of tooling systems.

Read MoreDustless, mobile solution for on-site wind turbine blade repurposing

Denmark-based Isodan Engineering ApS translated its expertise in mobile, shipping container-based newspaper recycling systems to solve a need for breaking down wind turbine blades on-site for reuse.

Read MoreTwenco develops sensors for smart molds and process control in resin infusion and composites welding

Non-invasive DEA and NDT Analyzer for multi-parameter monitoring, QA and control, including real time simulation feed and 3D process visualization across and through composite parts.

WatchNPROXX expands business into the U.S.

Type IV tank manufacturer cites national hydrogen investment, more supportive vehicle regulations and general expansion opportunities as reasons for its 2023 U.S. establishment goals.

Read MoreOverair's Butterfly eVTOL prototype to integrate composites-intensive design

Aiming for first flight tests in the latter half of 2023, Overair’s Butterfly aircraft uses Toray carbon fiber/epoxy prepreg strategically to cut weight on its battery-powered, quiet aircraft.

WatchHigh-performance, high-detail continuous 3D-printed carbon fiber parts

Since 2014, Mantis Composites has built its customer and R&D capabilities specifically toward design, printing and postprocessing of highly engineered aerospace and defense parts.

Read More