Trends

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

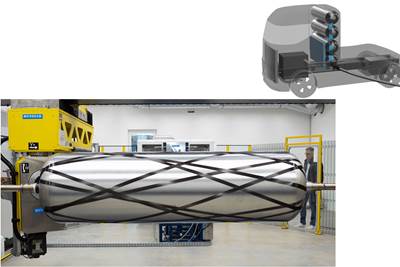

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreNASA picks Boeing’s Transonic Truss-Based Wing for Sustainable Flight Demonstrator project

With the help of NASA, Boeing will build, test and fly a full-scale demonstrator aircraft starting in 2028, gearing toward a greener, more fuel-efficient future aircraft.

Read MoreMingYang reveals 18-MW offshore wind turbine model with 140-meter-long blades

The Chinese wind turbine manufacturer surpasses its 16-MW platform, optimizes wind farm construction costs for 1-GW wind farms.

Read MoreChantiers de l’Atlantique reveals 66-meter, all-composite SolidSail mast

A technological feat, the large carbon fiber mast prototype targets the Silenseas sailing liner and sailing cargo ships for up to 40% reduction in CO2 emissions.

Read MoreStellantis to build Midnight eVTOL aircraft with Archer

Stellantis is to contribute advanced manufacturing technology and expertise, experienced personnel and capital, in addition to help stand up Archer’s new composites manufacturing facility, with the ultimate goal of becoming Archer’s exclusive contract manufacturer.

Read MoreVelocity Composites enters U.S. market with $100 million GKN Aerospace agreement

The composite material kits supplier expands into international markets with the development of its first U.S. manufacturing facility and a new agreement to support GKN aerostructures development.

Read MoreEuropean R&D project Bizente researches enzymatic technologies to recover thermosets

Through protein engineering, project partners molecularly modify enzymes and resins to make it possible to recover thermoset composites and give them a second life.

Read MoreCryomotive opens Hydrogen Storage Manufacturing Center

Cryomotive is to develop, manufacture and assemble Cryogas composite hydrogen tanks for commercial vehicles, buses and ships at new Pfeffenhausen site, accelerating hydrogen refueling systems production for zero-emission commercial vehicles.

Read MoreNCC announces life cycle assessment software results for construction

Study is undertaken to better understand LCA software tools to inform composites design and product development in decarbonization initiatives.

Read More