Processes

Composite 3D printing start-up Fortify secures funding

Fortify’s Fluxprint technology combines magnetics and digital light processing (DLP) 3D printing to produce composite parts with optimized mechanical properties.

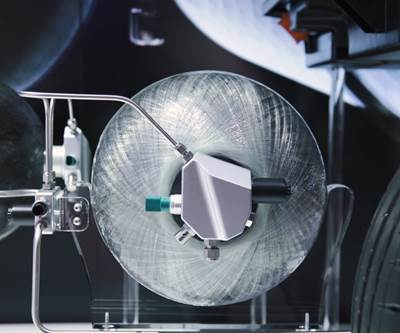

Read MoreFaurecia creates global center of expertise for hydrogen fuel tanks

Faurecia to invest in R&D for next-generation high-pressure hydrogen storage tanks that are more efficient and lighter, as well as in a test center to characterize tanks.

Read MoreAscent Aerospace invests in Thermwood LSAM machine

Ascent Aerospace to use large scale additive manufacturing to bring tooling solutions to market with significantly reduced lead times.

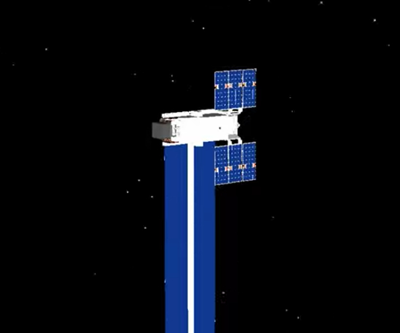

Read MoreNASA funds Made In Space project to 3D print spacecraft components in orbit

Made In Space’s Archinaut One spacecraft will demonstrate the ability to manufacture and assemble spacecraft components in low-Earth orbit.

WatchClean Sky 2’s PASSARO project targets one-shot OOA composite cockpit

Synergies with MOSHO project for NDT, repair and also developing cobots for 70% cut in cycle time.

Read MoreSicomin launches bio resin for HP-RTM processing

SR GreenPoxy 28 is a bio-based epoxy resin designed for fast cure, high performance, and more sustainable automotive manufacturing.

Read MoreCombining plastics and composites for Class A parts without tools

Plastics Unlimited’s patented TEC process cuts secondary finishing and meets multiple demands for medium-volume parts.

WatchFlame-retardant composite developed for additive manufacturing

CRP Technology’s Windform FR1 is a carbon fiber-filled flame retardant material for use with laser sintering.

Read MoreVABO Composites to build superstructure, mast for Royal Van Lent yacht

Lightweight marine composites production to be further advanced using robotic automation.

Read MoreSchunk Carbon Technology to 3D-print tooling using Anisoprint technology

The carbon fiber and ceramic solutions developer has adopted Anisoprint’s Composer printer and materials to accelerate its custom tooling operations.

Read More