Processes

Large, high-volume, infused composite structures on the aerospace horizon

Infused carbon fiber composite structures are not new, but they have never been built at the rates anticipated for next-generation, single-aisle aircraft. It is a daunting prospect — but a feasible one.

Read MorePlant Tour: STELIA Aerospace, Méaulte, France

Supplier of Airbus fuselage sections pushes boundaries of hybrid aerostructures production, assembly and thermoplastic composites.

Read MoreTackling the aerospace supplier’s dilemma: Scalability

Automation and robotics can go a long way toward increasing capacity and growing a business dedicated to aerospace manufacturing. But Trinity Precision has learned that refining the indirect and unseen aspects of its operations can be just as valuable.

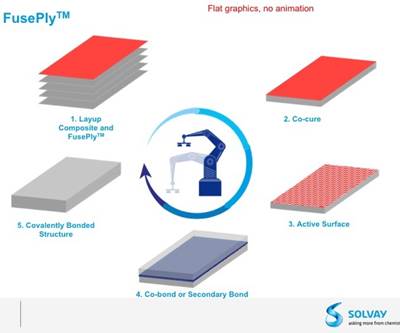

Read MoreSolvay epoxy-based film for prepregs

Solvay Composite Materials has developed FusePly, an epoxy-based film that is designed to co-cure with a prepreg and provide a chemically active surface that reacts with functional groups in adhesives to create a covalently bonded structure.

Read MoreLEWCO control system simplifies composite curing

The system, designed for use with Lewco industrial ovens, is designed for simpler use while providing more control over all aspects of the process.

Read MoreImpossible Objects printer speeds composite 3D printing

The CBAM-2 3D printing machine combines is said to rapidly produce stronger, lighter high-performance 3D composite parts.

WatchThermoplastic composites: Poised to step forward

The evolving role of thermoplastic materials and processes and their future in next-generation commercial aircraft.

Read MoreHuntsman introduces high-performance adhesives and composites systems

The company’s new edge and void fillers and stuctural adhesives are designed for aerospace composites.

Read MoreWeb Industries releases brochures highlighting aerospace composites solutions

The downloadable brochures highlight Web’s automation development center and its suite of aerospace solutions.

Read MoreArris Composites raises funding for high-speed composites manufacturing

The new proprietary process is said to produce low-cost carbon fiber composites for aerospace, automotive and other industries.

Read More