Finishing & Fastening

Addressing rivet hole drilling challenges for aerospace composites

Kennametal explores technological advancements in composite drilling, including stacked laminates, to meet aerospace applications and sustainability challenges.

Read MorePlasma moves beyond improved bonding to coatings, multifunctional composites

Plasmatreat cold plasma systems clean, activate surfaces and apply nanocoatings for dielectric barriers and more.

WatchFunctionalizing surfaces for sustainability

Riblets reduce drag, fuel consumption, CO2 emissions and noise while boosting power output, flow rates, speed and efficiency.

WatchMM-Welding solution automates, functionalizes composite joining

Ultrasonic joining has been used for decades, but is now being advanced to enable smart, automated fastening in composites and multi-material assemblies.

WatchDeveloping milling for CMC because grinding takes too long

Economical processes that can cut machining time by 70% are being tested on aeroengine turbine blade demonstrators by Hufschmied and DLR in the SCANCUT project.

Read MoreNovel insert technology enables arc stud welding with composites

FAUSST technology enables fast, reliably welded connection of metal components in composite structures.

Read MoreExploring powder coating for composites

Advancements in powder coating technology make it a viable surface finish for a growing number of composite applications.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreFiberJoints innovates composite bolted joints for reduced weight, cost and maintenance

Novel reinforcing patch uses braided sleeve to boost the load-carrying capacity of composite bolted joints.

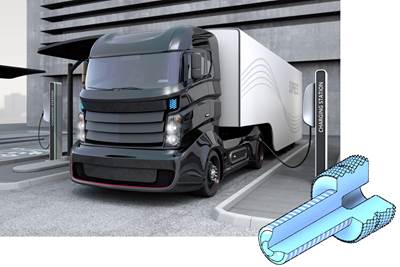

Read MoreCreating a composite battery insert-stud solution for EV trucks

Bossard worked with an OEM and Tier supplier team to meet tight electrical insulation and packaging tolerances while reducing tooling, molding and assembly costs.

Read More