Epoxies

How is tow spread?

ITA characterizes tow spreading processes and parameters as it develops new technology to speed production (100 m/min) and reduce width variation (<1mm).

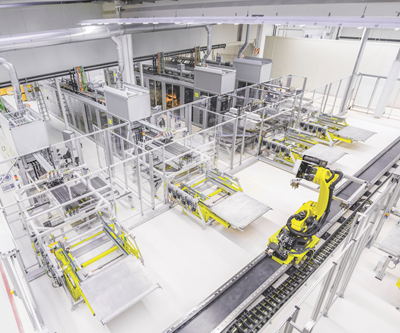

Read MoreRear wall reboot: One-stop, tow to tape to CFRP part

Audi and Voith Composites iterate the CFRP rear wall from R8 sports car to A8 luxury sedan via an automated production line able to output hundreds of parts per day.

Read MoreThis foiling racer is crazy fast thanks to composites

The Exocet racer’s hull and its foils, designed via computer model, are fabricated using hand layup and resin infusion methods, respectively, with PRO-SET epoxy.

Read MoreSicomin bio-based epoxy earns ECOBOARD qualification

The ECOBOARD Project Gold Level qualification applies to all surf, kite, wind and stand-up paddle boards made using any of Sicomin’s five GreenPoxy resin systems.

Read MoreSGL and Automotive Management Consulting announce cooperation to develop "xFK in 3D" technology

SGL Sigrapreg TowPreg used in patented 3D winding process to produce lightweight, optimized composite structures with efficiency, speed and reduced waste.

Read MoreFlexible cure prepreg finds use in marine and wind

It’s almost time for the 2018 Tour de France — no, not that one with the bicycles, but the Tour de France à la Voile. Hexcel (Stamford, CT, US) composite materials have been used for the race’s trimaran the DIAM 24’s mast construction from the outset.

Read MoreGabriel Performance Products acquires Royce International

The acquisition of Royce expands Gabriel’s offerings for the coatings, adhesives and composites markets.

Read MoreCarbon fiber/epoxy in production boats

Scout Boats and now Hinckley Yachts showcase how demand for lighter, faster performance pushes materials and process change.

WatchSicomin epoxy systems used in TAF's Sling aircraft

Sicomin has been working with The Airplane Factory to develop enhanced and efficient production methods for the flagship range of Sling aircrafts.

Read MoreAutomated Preforming, Part 6: Coriolis Composites

Pioneer in automated fiber placement (AFP) advances preforms for overmolded thermoplastic composites enabling production of one automotive part every 20 seconds.

Watch