Electric Vehicles

Plastic Omnium announces proposed acquisition of ACTIA Power, equity stake in Verkor

The French automotive storage solutions company aims to expand its electric vehicle capabilities with new electrification and battery partners.

Read MoreAimplas joins LIGHTCAR project to develop eco-friendly composite materials

Funded by the Valencian Innovation Agency, novel long fiber thermoplastics aim to lighten electric vehicle batteries by 50-70%

Read MoreEvonik, Vestaro consortium partners develop EV Pure Performance Battery

Novel approach to high-voltage GF-SMC battery module housing design increases battery cell capacity, enables flexible adjustment of the number of modules and can be catered to a variety of vehicle architectures.

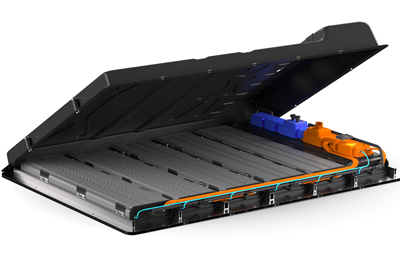

Read MoreMulti-material toolbox for cost-effective, scalable EV battery enclosure design

Mexico-based automotive Tier 1 Katcon has developed a “toolbox” of material, process and joining options aiming to serve a range of electric vehicle requirements.

Read MoreSumitomo Bakelite eAxle demonstrator drives forward novel thermoset composite material applications

The fully functional eAxle, a single, compact unit that directly powers electric vehicles, will showcase the project’s newly developed materials and assemblies and validate efficiency improvements and increased design flexibility.

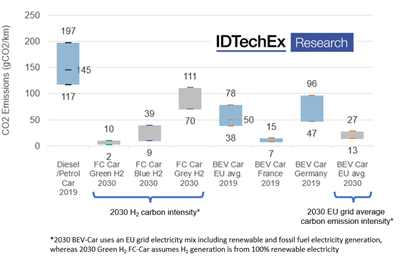

Read MoreIDTechEx outlook suggests hydrogen fuel prices, volume are affecting fuel cell vehicle rollout

Report on the current state of FCEV development studies the great lengths made by Toyota, Hyundai and Honda to build industry momentum, and the current state of green hydrogen’s expense and volume production.

Read MoreTeijin Automotive Technologies expands composites footprint in China to meet growing demand for EVs

Construction and commercial operations of two new composites manufacturing facilities in Changzhou and Shenyang to support automotive customers globally, with targeted annual sales of $2.0 billion by 2030.

Read MoreProtocol aims to improve testing of thermal runaway for composite EV battery enclosures

Hyundai-Kia and Forward Engineering developed a resistive, heater-based material test, recently published as a UL standard, to aid and speed composite battery enclosure development.

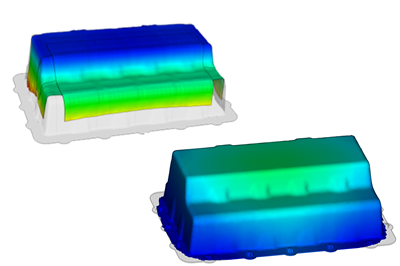

Read MoreHybrid battery cover: CAE approach

A Q&A with Benedikt Fengler, co-founder and composites simulation specialist for Simutence provides a more in-depth take on moldfilling, warpage and assembly simulations performed in HRC Group’s SMC battery cover feasibility study.

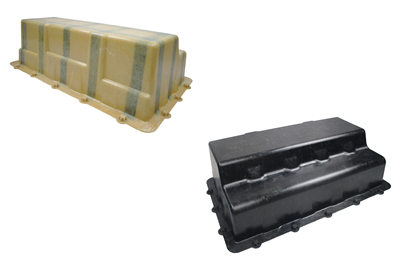

Read MoreSMC material configurations tailored to automotive battery enclosure design

SMC battery cover offers various module configurations, levels of performance, mass and cost for electric vehicles.

Watch