Electric Vehicles

Sumitomo Bakelite Europe conference highlights importance of composites for electric mobility

Composites for Future Mobility Conference attracts more than 50 delegates from OEMs, Tier suppliers and research institutions which are finding numerous composite opportunities in electric motors, UAM.

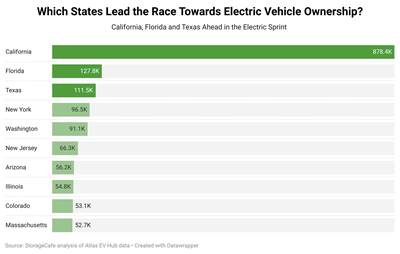

Read MoreElectric vehicle analysis ranks most-ready hubs for EV adoption

StorageCafe examines 100+ U.S. metropolitan areas and ranks the top 10 by number of EVs, public chargers, electricity cost, infrastructure challenges, clean energy, EV insurance costs, local incentives and more.

Read MoreSolvay features Xydar polymer for high-heat EV battery module insulation

Xydar LCP G-330 HH is a new glass-filled liquid crystal polymer grade designed to increase passengers’ safety in the event of battery thermal runaway.

Read MoreBMW Group to bring iX5 Hydrogen pilot fleet into service in 2023

A fleet of under 100 vehicles, featuring BMW fuel cell technology and 700-bar CFRP storage tanks, will be deployed for international demonstration and trial purposes.

Read MoreSeat frame demonstrates next-generation autocomposites design

Light weight, simplified/cost-effective manufacturing, passenger comfort and safety informed materials and process innovations and won awards for the 2022 Toyota Tundra‘s second-row seat frame.

Read MoreThe state of recycled carbon fiber

As the need for carbon fiber rises, can recycling fill the gap?

Read MoreCarbon Revolution to list in U.S. via business combination with Twin Ridge Capital Acquisition Corp.

Following the transaction, the Australian carbon fiber wheel supplier and manufacturer will be well positioned for rapid growth and adoption into additional automotive programs.

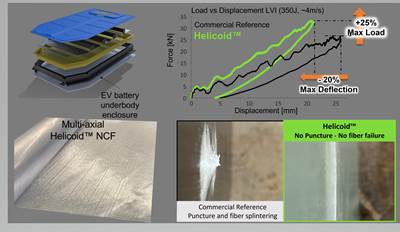

Read MoreHelicoid Industries releases three use cases of Helicoid technology

Use case applications with Helicoid technology implementation demonstrated mechanical performance improvements, such as impact resistance and strength.

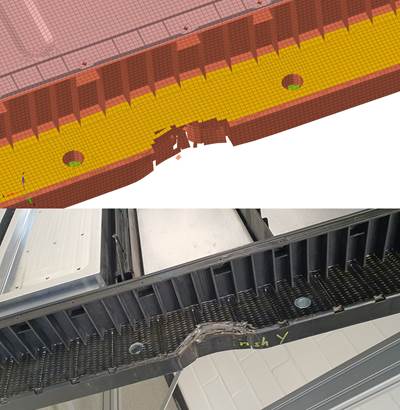

Read MoreBattery enclosure demonstrator testing proves EV feasibility, launches series production projects

Kautex Textron and Lanxess jointly developed and tested a PA6 technology demonstrator, reinforced with locally placed continuous fiber blanks, which passed all important mechanical, thermal tests.

Read MoreOSCiAl, Genius graphene nanotubes advance EV battery pack properties

Addition of graphene nanotubes to fiberglass-filled polyphenylene sulfide solution make it possible to preserve high thermal and chemical resistance together with stable electrical conductivity.

Read More