Design & Tooling

Preforming goes industrial: Part 1

ATL and AFP-based preforming options now abound for processing dry and/or impregnated reinforcements as quickly as 1 minute or less with potential yearly part yields in the millions.

Watch3D printed tools are in production at Dassault Falcon Jet

The trend of employing polymeric additive manufacturing (AM) or 3D printing for composite tooling is growing.

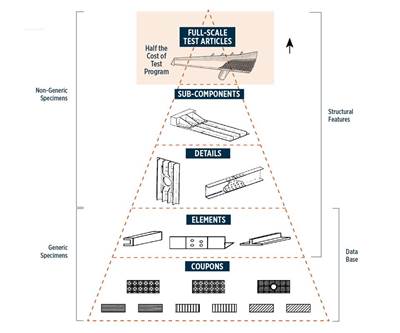

Read MoreAccelerating materials insertion: Where do virtual allowables fit?

In the quest to reduce the time and cost for aerocomposite design allowables development, will conventional physical testing and virtual testing go head-to-head or work side-by-side?

Read MoreCurved pultrusion? No longer an oxymoron

Radius-Pultrusion process offers linear or curved profiles.

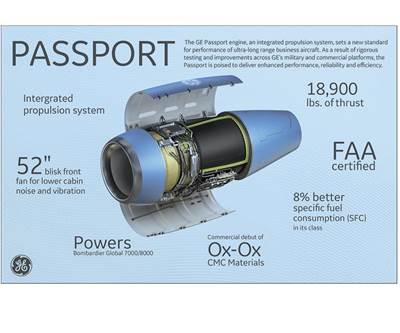

Read MoreCeramic matrix composites: Hot engine solution

Disruptive designs for composites operation in 1093°C zones.

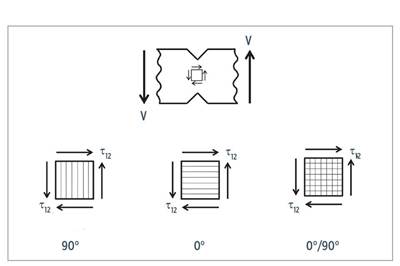

Read MoreBest practices for V-notched shear testing of composites

In my October 2015 column, I wrote an overview of the widely used V-notched shear test methods for composite materials. In this column, we focus on some additional best practices when performing V-notched shear testing of fiber-reinforced composites.

Read MoreKey takeaways from JEC World 2017

A quick read of the composites tea leaves after JEC World 2017.

Read MoreInFactory Solutions with Airbus

Airbus spin-off supplying Industry 4.0 systems for composites completes first qualification and discusses future developments for defect position visualization.

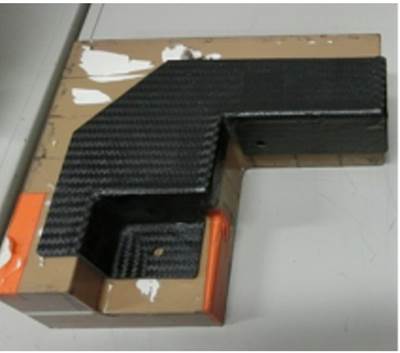

WatchMaking composite parts from 3D printed paper molds

Honda made autoclave-capable molds at one-tenth the cost of CNC-machined metal using Mcor's SDL technology.

WatchPeople on the move: March 2017

Here is this month’s people on the move news in the composites industry.

Read More