Design & Tooling

Zenvo Automotive announces partnership with Managing Composites

New benchmarks for performance, design and safety can be anticipated with the Aurora platform, backed by Managing Composites’ support of the hypercar and supercar industry, and its extensive knowledge in composite materials and simulation.

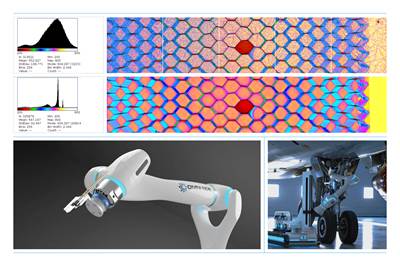

Read MoreAutomated NDE equipment brings new inspection capabilities

CAMX 2023: Omni-NDE combines cobots/small robots with novel sensors to provide automated, contactless inspection of composites.

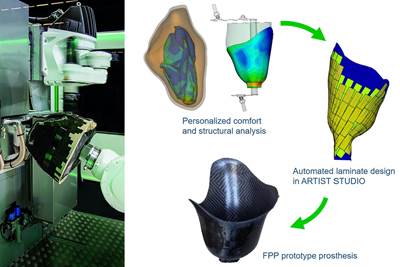

Read MoreCevotec’s fiber patch placement is part of digital process chain for automated composite prosthetics

Multiple partners work to develop automated data collection, composite laminate generation for customized medical applications using FPP technology in German-funded Patch2Patient project.

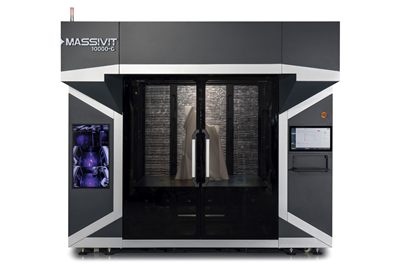

Read MoreLarge-scale additive system prints industrial molds for composites

CAMX 2023: The Massivit 10000-G, with gel dispensed printing offers an ultra-fast, sustainable and cost-effective way to digitize isotropic mold production for high-quality and more reliable composite parts.

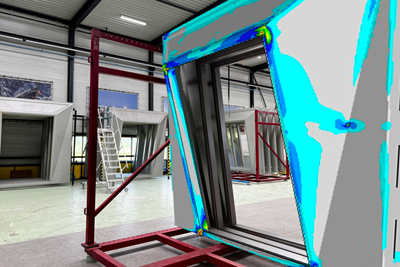

Read MoreSolico engineers sustainable Duplicor composite façade for The Pulse

Using long-term client Holland Composites’ 100% bio-based composite solution, Solico optimized the engineering of the new building’s approximately 1,100 composite elements.

Read MoreOptimized approach to predict delamination failure in CFRTP structures

ARRK Engineering and Mitsui Chemicals improved delamination prediction accuracy to help optimize absorbed energy/failure load for an overmolded TAFNEX CF/PP UD tape bumper beam.

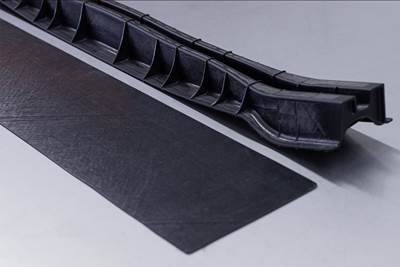

Read MoreCarbon fiber tooling addresses aerocomposites pain points

CAMX 2023: The result of extensive R&D, BlackBoard by Harcourt Industrial enhances efficiency, reduce costs and improve overall manufacturing performance compared to Invar tools.

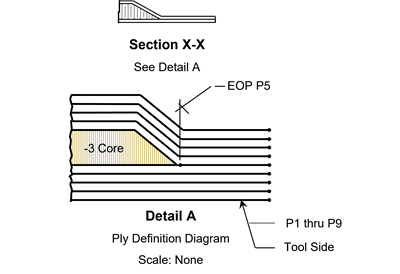

Read MoreThe basics of composite drawing interpretation

Knowing the fundamentals for reading drawings — including master ply tables, ply definition diagrams and more — lays a foundation for proper composite design evaluation.

Read MoreMachine, equipment investment strengthens Ruckus Composites’ research, innovation

CNC services expansion, universal testing machines and advanced inspection enable Ruckus to delve deeper into the study and evaluation of carbon fiber damage, as well as nondestructive and destructive testing.

Read MoreVericut 9.4 enhances manufacturing workflow connectivity

CGTech’s latest release for the standalone software includes streamlined optimization, improved reviewer files, tool data enhancements and a new ToolsUnited interface.

Read More