Design & Tooling

Tooling up for larger launch vehicles

NASA and Janicki Industries demonstrate composites’ cost advantage in tooling for fabrication of 10m/33 ft diameter payload fairing for next-generation launch vehicle.

Read MoreOptimization software improves small, low-cost satellite design

Ames Research Center’s (Moffett Field, Calif.) designs and builds a low-cost, small spacecraft on a quick turnaround, using a modular strategy based on commercial off-the-shelf (COTS) parts and with the aid of several design software packages and finite element solvers.

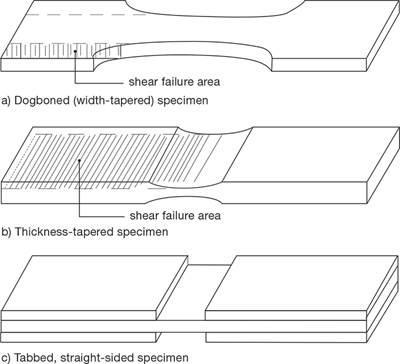

Read MoreThe Double-Notch Shear test specimen for composite materials

Dr. Donald F. Adams (Wyoming Test Fixtures Inc., Salt Lake City, Utah) recommends best practices for double-notch shear test specimens.

Read MoreRevisioning the Viper: Clamshell hood challenge

Autoclave-cured carbon-fiber prepreg hood/fender combo proves as technically formidable as it is visually stunning.

Read MoreSoftware isolates, identifies porosity-related flaws in tooling from fuselage test data

Software and composites manufacturing data specialist NLign Analytics, a division of Etegent Technologies (Cincinnati, Ohio) helps identify and track product flaws caused by tooling porosity.

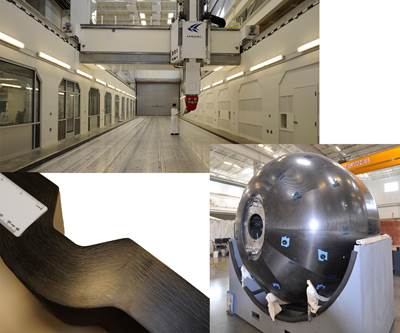

Read MoreJanicki Industries: Breaking the mold

Once known only as a toolmaker, Janicki offers unique precision, production capability and problem solving as it pioneers leading-edge composites technology.

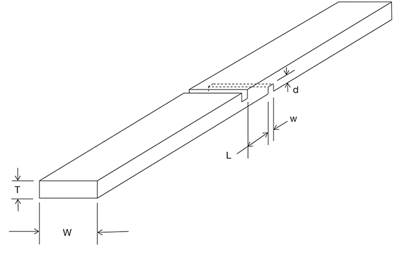

Read MoreThickness-tapered unidirectional composite specimens

Sometimes a testing concept is known for a long time but is never developed into an established test method.

Read MoreBuilding a better tail boom

Out-of-autoclave carbon fiber/thermoplastic demonstrator is a 30 percent lighter drop-in replacement for an existing aluminum design.

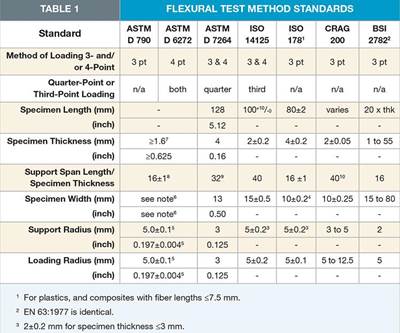

Read MoreFlexural test method standards for composite materials

Dr. Donald F. Adams (Wyoming Test Fixtures Inc., Salt Lake City, Utah) proposes a common-sense standard method for flexural testing of composite materials.

Read MoreFaster cycle, better surface: Out of the autoclave

GM is first automaker to use Class A CFRP parts from new pressure-press technology.

Read More