Composites Basics

Top 10 Considerations When Buying a CNC Machine for Composites

For a CNC machine to continue to meet or exceed a company’s needs, it must be built and spec’d with these needs in mind.

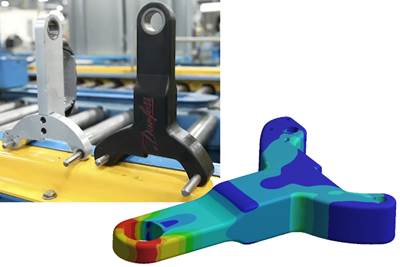

Read MoreHow to validate 3D-printed composite part performance

Integrated Computational Materials Engineering (ICME) workflow simulates composite material performance to speed development, optimize performance and reduce costs for a redesigned 3D-printed CFRP bracket.

Read MoreHow ultrasonic testing can find flaws in composite materials

As composite applications expand, so does the demand for more capable inspection systems. Ultrasound has proven to be effective when it comes to in-depth, sophisticated testing.

Read MoreThe importance of resin selection

Explore how resins can affect a composite’s properties and why we should consider resin choice with the same significance as fiber.

Read MoreThermoplastic composites at Oribi Composites: CW Trending, episode 4

Oribi Composites’ Matt Christensen discusses the origin of the Colorado-based thermoplastic composites fabricator, his role at the company, current products and programs, and the real potential for use of thermoplastic composites in wheels.

WatchUniversity of Illinois Chicago leverages SwiftComp software to improve understanding of porous coatings

Software to accelerate development and adoption of new composite materials for manufacturing by predicting effects of porosity level on strength.

Read MoreHow to: Getting the most from your mold release

Mold release specialist AXEL Plastics offers dos and don’ts for cleaning, stripping and preparing molds for composites manufacturing. (Sponsored)

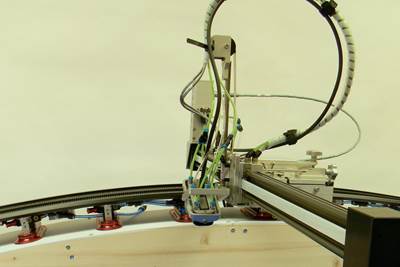

WatchBraided preforms and resin infusion for next-generation aerocomposites

Spintech shows significant cost and labor savings using its Smart Tooling, dry fiber preforms and RTM/VARTM technology on aircraft wing and inlet duct demonstrators.

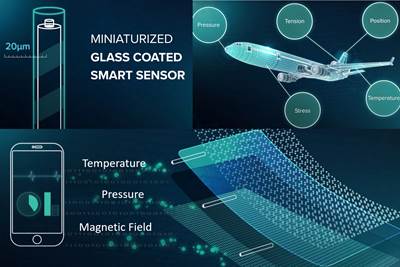

WatchContactless measurement of temperature, pressure in composites

Magnetic microwires enable contactless measurement of temperature and pressure during cure and in service.

WatchLight resin transfer molding

Magnum Venus Products introduces its new Fast Flow light resin transfer molding (LRTM) system, which offers reduced injection times, minimal waste, and minimal post-processing.

Watch