Carbon Fibers

Modular drill platform assists with composite drilling

CAMX 2023: The KenTip FS Modular Drill platform from Kennametal can help maximize efficiency with straight-bodied flutes, ultra-high polished chip flutes and smart wrench insertion.

Read MoreCRP 3D printing composites optimize Formula SAE team’s racing performance

Long-term CRP USA and UVic Formula Racing partnership has culminated in the development of versatile, durable carbon fiber-filled components that continue deliver on the track.

Read MoreOn the radar: Proliferation of propellers drives CFRP blade production

As propulsion efficiency advances, so too do general aviation and AAM aircraft designs to account for additional efficiency targets. Composite propeller blades are key.

Read MoreZenvo Automotive announces partnership with Managing Composites

New benchmarks for performance, design and safety can be anticipated with the Aurora platform, backed by Managing Composites’ support of the hypercar and supercar industry, and its extensive knowledge in composite materials and simulation.

Read MoreThe lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MoreImpulse Space secures $45 million to support vehicle development, production

Developer of in-space transportation vehicles using CFRP tanks raises capital investment from Raytheon Technologies (RTX) Ventures.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreSwancor obtains GRS-certified recycled carbon fiber

One hundred percent recyclable fibers have been achieved from composite components made from the company’s EzCiclo thermoset resin.

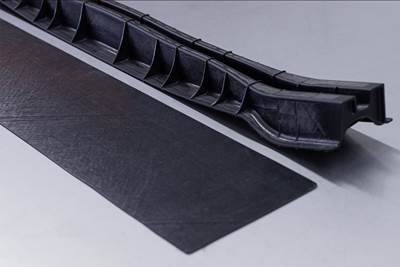

Read MoreOptimized approach to predict delamination failure in CFRTP structures

ARRK Engineering and Mitsui Chemicals improved delamination prediction accuracy to help optimize absorbed energy/failure load for an overmolded TAFNEX CF/PP UD tape bumper beam.

Read MoreCarbon fiber tooling addresses aerocomposites pain points

CAMX 2023: The result of extensive R&D, BlackBoard by Harcourt Industrial enhances efficiency, reduce costs and improve overall manufacturing performance compared to Invar tools.

Read More