ATL/AFP

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

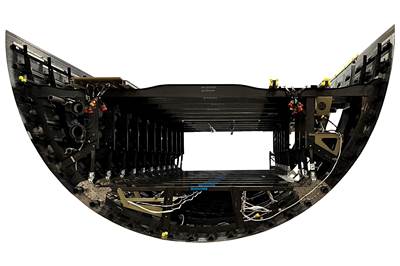

Read MoreSTUNNING project completes lower half of MFFD

Clean Sky project has delivered the 8 × 4 meter welded aerostructure component, aided by advanced thermoplastic composite technologies and smart robotics.

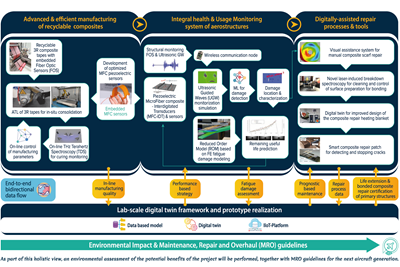

Read MoreEU-funded GENEX project to develop digital twin framework for aircraft lifecycle tracking

Novel digital framework to enable holistic and comprehensive data capture through the entire aircraft lifecycle, supporting composite component/structure manufacture optimization and maintenance.

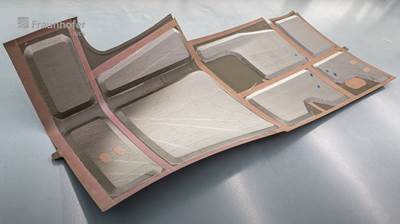

Read MoreOptimizing AFP for complex-cored CFRP fuselage

Automated process cuts emissions, waste and cost for lightweight RACER helicopter side shells.

WatchNovel dry tape for liquid molded composites

MTorres seeks to enable next-gen aircraft and open new markets for composites with low-cost, high-permeability tapes and versatile, high-speed production lines.

WatchPlant tour: Avel Robotics, Lorient, France

From AFP hydrofoils to more efficient aircraft parts, Avel uses digital design, multiprocess production and a rule-breaking approach for complex 4D composites.

WatchCFRTP upper stage propellant tank

PROCOMP uses in-situ consolidation AFP and ultrasonic welding to demonstrate lightweight, novel tank design.

Read MoreCannon Tipos, Coriolis Composites mold complex automotive structural part from single preform

Dosing equipment for precise injection and mold engineering enable near-net-shape dry preform for HP-RTM CFRP composite part with rapid cycle time.

Read MoreCygnet Texkimp builds high-precision slitter spooler rewinder for industry trials

Demonstration machine can precisely slit and wind up to 48 tapes from continuous thermoset UD carbon fiber prepreg, with additional material compatibilities.

Read MoreDrawing design cues from nature: Designing for biomimetic composites, Part 1

Biomimicry is an interdisciplinary methodology that can inform composites design and manufacturing via use of more effective and sustainable materials, structural fabrication and technological practices.

Read More