SABIC Innovative Plastics

2500 City West Boulevard

Suite 650

Houston, TX 77042 US

713-430-2301

productinquiries@sabic.com

IS THIS YOUR COMPANY?

As Seen On ÂÌñÏ×ÆÞ

SABIC Innovative Plastics Supplies the Following Products

- ABS (and ABS/PVC Alloy)

- Acetal

- ASA Copolymers & Alloys

- Polycarbonate

- Polycarbonate/ABS Alloys

- Polycarbonate/Polyester Alloy

- Polyester (Thermoplastic) - PET Type

- Polyester (Thermoplastic) -PBT Type

- Polyetherimide

- Polyethersulfone

- Polyethylene - HDPE

- Polyethylene - LDPE

- Polyethylene - LLDPE

- Polyimide (Thermoplastic)

- Polyphenylene Ether/Oxide-Based Resins

- Polyphenylene Sulfide (PPS)

- Polyphthalamide (PPA)

- Polypropylene (including Copolymers)

- Polystyrene & Styrene Copolymers

- Polysulfone

- Stock Shapes - Film, Rod, Tube, Sheet

Trade Names Offered by SABIC Innovative Plastics

- XENOY

- STAT-KON

- KONDUIT

- LUBRILOY

- NORYL PPX

- COLORCOMP

- LNP

- ULTEM

- THERMOCOMP

- CYCOLAC

- VERTON

- GELOY

- STAT-LOY

- NORYL GTX

- LEXAN

- REMEX

- LUBRICOMP

- FARADEX

- CYCOLOY

- VALOX

- XYLEX

- NORYL

Editorial, News, and Products

-

Schrödinger advances materials informatics for faster development of next-gen composites

Cutting time to market by multiple orders of magnitude, machine learning and physics-based approaches are combined to open new possibilities for innovations in biomaterials, fire-resistant composites, space applications, hydrogen tanks and more.

-

On the radar: Innovations in composite battery enclosures

A look at recently reported design, material and process innovations for composites-intensive battery enclosures, developed to support the ramp-up of EV and AAM vehicles.

-

SPE automotive names winners for 53rd annual automotive innovation awards program

SPE’s annual Automotive Innovation Awards highlighted several composite part designs in vehicle safety, comfort and efficiency.

-

Airbus works to improve the life cycle of composites in future aircraft

This companion article to CW's September 2024 Airbus Illescas plant tour discusses recycling, LCA, biocomposites, Fast Track technologies, qualification and more.

-

Top 10 ÂÌñÏ×ÆÞ products of 2023

A variety of novel materials, processes targeting the composites industry’s light weight, sustainability and more rapid production efforts made CW’s top 10 most popular product pieces of 2023 based on Google Analytics.

-

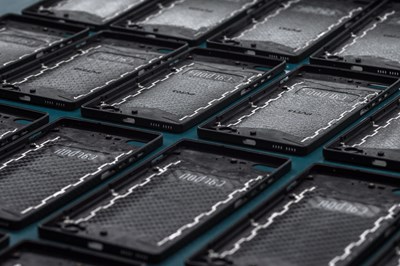

SABIC LNP Thermocomp WF006V compound optimizes electronics

Debut of the glass fiber-reinforced grade has the potential to help improve LDS antenna performance, dielectric properties and aesthetics in consumer electronics, appliances.

-

SABIC launches fiber-reinforced, intumescent, fire-retardant resins

SABIC PP compound H1090 and Stamax 30YH611 resins are well suited for extruding and thermoforming large, complex EV battery pack components for automotive.

-

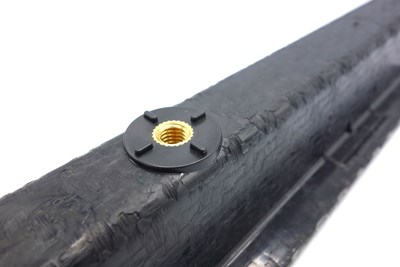

Robotized system makes overmolding mobile, flexible

Anybrid’s ROBIN demonstrates inline/offline functionalization of profiles, 3D-printed panels and bio-based materials for more efficient, sustainable composite parts.

-

Carbon Mobile, SABIC to develop, deploy advanced carbon fiber in connected devices

Collaboration aims to deliver the next generation of thinner, lighter, stronger and more sustainable composite materials used in consumer electronics and automotive industries.

-

SABIC debuts EN45545 rail-compliant, fiber-reinforced compound

LNP Thermocomp AM DC0041XA51 offers the rail industry a solution that can be used for on-demand printing of large, complex exterior and interior parts in relatively small build numbers.

-

Large-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

-

Mass, cost, durability improvements: EV battery enclosures, Part 2

As interest grows in composite battery covers and trays, composite materials suppliers work to meet current and future needs of automakers, battery module producers.

-

Plant tour: National Institute for Aviation Research, Wichita, Kan., U.S.

NIAR, located at Wichita State University in the heart of the American aerospace manufacturing industry, has evolved to become a premier hub of teaching, R&D, creativity and innovation.

-

Stratasys collaborates with Lockheed to qualify composite materials for space, aviation end-use parts

Report made public by Metropolitan State University of Denver delivers qualification data for Antero 840CN03 for additively manufactured end-use parts requiring high thermal and chemical resistance, and ESD properties.

-

SABIC, Dongfeng Motors produce composite truck-mounted toolbox

Thermoformed glass fiber-reinforced PP laminate inserts are overmolded with Stamax resin for a 30% lighter part.

-

FITS Air thermoplastic sandwich panels enable low-cost, low-weight, sustainable aircraft interiors

FITS Air and FITS Base sandwich panels provide alternative material avenues for aerospace and other industries, including low weight, low part production cost, thermoformability and recyclability.

-

SPE Automotive Division names 36 finalists for annual Automotive Innovation Awards Gala

Category and grand award winners selected by the Blue Ribbon judging round Oct. 1 will be announced during the gala on Nov. 10, 2021. Submissions are described below.

-

SABIC launches bio-based, amorphous polymers to support sustainability goals

The ISCC-designated high-performance polyetherimide (PEI) materials offer the same mechanical properties as incumbent Ultem materials, with a focus on challenging applications and a reduced carbon footprint.

-

Corrosion-resistant resins enable FRP petrochemical plant equipment

Spanish fabricator Ollearis used AOC resins and glass fiber filament winding to meet design and cost requirements for combustion unit tank and pipes.

-

Stratasys, Champion Motorsport team up to test 3D-printed core technology

Stratasys proves out carbon fiber-wrapped, printed core for toolless, customizable manufacture, on aerodynamic prototype and production parts for a winning racecar.

-

Additive manufacturing adds versatility to large marine structures

Dive Technologies and Moi Composites are among those extending composite 3D printing’s design flexibility past prototyping and into customizable end-use parts.

-

Markforged next-generation fiber-reinforced 3D printer

Markforged will debut its newest continuous fiber-capable 3D printer, the FX20, at Formnext in November 2021.

-

Diab acquires SABIC’s ULTEM foam production line

The recyclable PEI thermoplastic foam will be incorporated into Diab’s portfolio under Divinycell U to be produced, sold and further developed.

-

SABIC, Local Motors conduct feasibility study for reprocessed, 3D-printed thermoplastic parts and shavings

Anticipating the wider adoption of LFAM, the study explored more sustainable alternatives to landfilling large, printed parts, with results indicating the potential for material reuse.

-

EconCore thermoplastic honeycomb cores deliver high-heat performance, facilitates recyclability

Honeycomb cores incorporate Sabic NORYL GTX resin for improved dimensional stability, lower water absorption and demonstration of thermoset composite skin compatibility.

-

Resin shortages continue to affect composites supply chain

Power outages caused by mid-February’s U.S. winter storms led to immediate shortages from Gulf Coast petrochemical companies. Fabricators continue to report shortages.

-

SABIC novel bio-based LNP compound demonstrates reduced carbon emissions

Flame-retardant carbon fiber-reinforced compound offers a 17% reduced carbon footprint and does not alter the polymer properties of the incumbent material.

-

Hybrid, large-format additive tooling: Lighter, faster, less costly molds for big parts

Additively manufactured cores, CFRP face skins produce large tools for prototype, low-volume aerostructure parts.

-

New 3dpbm market analysis division presents AM industry study results

Analysis of composites additive manufacturing performed by the new market analysis and consultancy group shows the market generating $10.6 billion in yearly revenues by 2030.

-

Composites speed concrete facade fabrication

The 45-story One South First building, on the 11-acre Domino Park campus in Brooklyn, N.Y., features a geometrically complex concrete facade made, in part, with composite molds fabricated using large-format additive manufacturing.

-

DSM, SABIC, UPM Biofuels create bio-based Dyneema

The partners are transitioning HMPE Dyneema fiber to a plant-based feedstock without sacrificing product performance.

-

Corrosion-resistant composite piping over the long haul

Three decades of lessons learned using corrosion-resistant glass fiber-reinforced composites in piping at SABIC’s Netherlands chlorine production plant.

-

Continuous fiber-reinforced thermoplastics data added to CAMPUS database

The new data, which will be released in October, is the result of an ongoing material standardization and characterization effort led by German reinforced plastics company AVK.

-

Research project reports potential for tape inserts in injection molding

The research consortium, led by the Aachen Center for Integrative Lightweight Production and the Institute for Plastics Processing at RWTH Aachen University, will present its results at K 2019.

-

High-speed, high-rate thermoplastic composites manufacturing

A novel process from SABIC and Airborne promises high-speed, high-rate production of thermoplastic composite laminates for mainstream manufacturing and a variety of applications.

-

Evolving into continuous fiber reinforcements

SABIC expanded its materials offerings in short-fiber injection and long-fiber thermoplastic (LFT) materials to include continuous-fiber thermoplastic tapes.

-

Mallinda raises strategic investment from SABIC

The Colorado startup aims to scale up its pre-cured thermoset composite materials for use in the transporation industry.

-

Saudi Aramco to acquire majority stake in SABIC

Saudi Aramco has signed a share purchase agreement to acquire a 70-percent majority stake in SABIC in a private transaction.

-

Massachusetts-based startup raises funding to launch carbon fiber super-composite

Boston Materials has raised $1.75 million in seed funding to launch its Carbon Supercomposite, which uses a patented Z-axis reinforcement technology in a carbon fiber composite.

-

JEC World 2019 preview: SABIC

SABIC (Pittsfield, Mass., U.S., 6/P12) is highlighting the progress of its Digital Composites Manufacturing line, an automated digital systems for rapid, large-scale laminate manufacturing, via a 360-degree virtual reality experience.

-

SPE recognizes first injection molded thermoplastic energy absorber

The award-winning energy absorber is made with XENOY Polycarbonate/Polybutylene Terephthalate (PC/PBT) resin from SABIC.

-

Drones: Composite UAVs take flight

First seen in defense applications, unpiloted aircraft development is surging in the commercial world, enabled by a host of new material, process and assembly technologies.

-

SABIC launches new filaments for fused deposition modeling

The new filaments add to the company’s fast-growing additive manufacturing materials portfolio.

-

Episode 17: Gino Francato, Sabic; Arno van Mourik, Airborne; John O'Connor, Siemens

Business leaders at Sabic, Airborne and Siemens discuss a collaboration by the three companies to develop the UDMAX thermoplastic laminate manufacturing system.

-

JEC World 2018: The highlights

JEC World is the composites industry’s largest trade show and did not disappoint this year.

-

European SAMPE meeting explores composites innovation

High spots from SAMPE Europe’s Summit 17.

-

Small companies, long-term impact

In a time known for owner “exit strategies,” longevity in family-owned composites businesses is heartening.

-

3D printed composite parts provide solution for UAV

New technology uses long carbon fibers to boost strength and stiffness for small yet high-performance aircraft.

-

Precision design for deployable space structures

Enabling SMAP mission success, unprecedented design requirements were deftly managed using composites in the largest unfurling and rotating reflector to date.

-

Materials & Processes: Fiber formats for composites

Fibers used to reinforce composites are supplied directly by fiber manufacturers and indirectly by converters in a number of different forms, which vary depending on the application. Here's a guide to what's available.

-

Supply and demand: Advanced fibers

Demand for advanced fiber, virgin and reclaimed, is on an upswing after a dip during the recent recession. Fiber suppliers are gearing up to meet an expected increase in demand as manufacturers in a number of composites end-markets scale up or start up part development and production programs

-

Turnkey manufacturing systems: Materials, markets and maturation

Automated production cells promise affordability and less risk in scaling up composites production, but are they really the path forward?

-

CW Ideas in Action

Ideas are just ideas until someone does the hard work of putting them into action and seeing results. CW's editors, therefore, inaugurate an annual review of Ideas in Action, celebrating a handful of hot concepts that could make those who conceived them "household names."

-

Green resins: Closer to maturity

As more players approach the market, R&D expands, but overall market growth in the composites arena is still slow but steady.

-

A growing trend: 3D printing of aerospace tooling

Toolmakers and OEMs are embracing additive manufacturing for customized, rapid tools, masters and jigs.

-

In-orbit-deployable radar dish

Aramid/PEI delivers flexibility, strength and precision for space-based reflector

-

3D Printing: Niche or next step to manufacturing on demand?

With and without fiber reinforcement, additive manufacturing is making an impact, but to what end?

-

Supply and demand: Advanced fibers (2015)

Demand for advanced fiber, virgin and reclaimed, is on an upswing after a dip during the recent recession. Fiber suppliers are gearing up to meet an expected increase in demand as manufacturers in a number of composites end-markets scale up or start up part development and production programs.

-

CAMX 2014 show report

Bigger, better and more inclusive than any previous U.S. composites trade event, the inaugural show turns North American eyes forward to the future.

-

ACMA COMPOSITES 2013 review

Once again, cautious optimism, an abundance of revealing research and a parade of notable new products are ACMA convention keystones.

-

Market Outlook: Surplus in carbon fiber's future?

Participants at CW’s Carbon Fiber 2012 Conference see one coming as early as 2016.

-

2011 High-Performance Resins Highlights

Attendees reviewed the current state of advanced resin technology and the tests that lay ahead for expanding composites into new applications and markets.

-

Carbon fiber food tray arm: Better and cheaper

CW Conferences director Scott Stephenson summarizes the substance of a presentation at the High Performance Resins 2011 conference (Seot. 27-28) by Mohammad Moniruzzaman (SABIC Innovative Plastics, Pittsfield, Mass.), who detailed the development of a carbon fiber composite food tray arm for passenger aircraft seat backs.

-

Interior innovation: The value proposition

OEMs and Tier suppliers ask materials and molding processes to go “green” and do more for less.

-

CNTs ride a rising tide of nanotech optimism

Dr. Louis Pilato offers facts, figures and comment on the growing utility of carbon nanotechnologies in composites applications.

-

In-mold alternatives to postmold decoration

CT reviews viable, versatile technologies that reduce the time and cost of finishing composite parts.

-

Thermoplastic composites: Inside story

Reinforced thermoplastics buy their way into structural aircraft interior components.

-

Low-cost methods realize high-concept Superbus

Multifunctional mass-transport vehicle concept takes shape via resin-infused carbon/epoxy and vacuum-formed glass-reinforced thermoplastic sandwich construction.

-

What's new in automotive front-end modules?

Composite and hybrid composite/metal solutions reduce cost and weight and increase assembly efficiency on passenger vehicles.

-

HYBRID COMPOSITE PANEL UNLOCKS HIDDEN VALUE

SMC and flax/polypropylene come together in a single component to add functionality to Nissan’s Sentra.

-

Engineering Insights: Glass/Thermoplastic Hood Steps Toward Commercialization

The hood design for Hyundai’s QarmaQ concept car is evaluated against European and Japanese pedestrian safety requirements.