Evolving into continuous fiber reinforcements

SABIC expanded its materials offerings in short-fiber injection and long-fiber thermoplastic (LFT) materials to include continuous-fiber thermoplastic tapes.

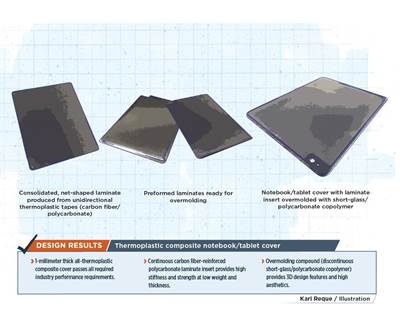

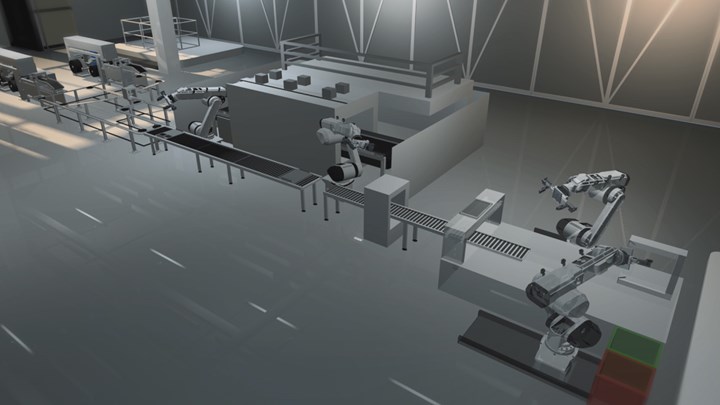

SABIC has teamed with Airborne to develop the Digital Composites Manufacturing Line, which rapidly lays up UD thermoplastic tapes into near-net-shape flat laminates (left), then consolidates them in a contact-heating process (middle), and finally trims and inspects them (right). Airborne is expected to begin shipping custom laminates to consumer-electronics customers next year. Source | SABIC.

SABIC (Bergen op Zoom, Netherlands) decided, in 2012, to get into thermoplastic composite tapes. The company already had a broad polymer offering in short-fiber injection and long-fiber thermoplastic (LFT) materials (both with glass and carbon fiber reinforcement), so continuous-fiber tapes were a logical extension of its core technology. Additionally, the gravitation toward thermoplastic tapes aligned with industry trends favoring materials and process technologies with lower energy consumption and that are more sustainable and enable a healthier environment for workers. SABIC became convinced there was plenty of untapped opportunity for thermoplastic tapes in multiple markets (see “Consumer electronics: hybrid composite covers”).

Initially, the team involved with thermoplastic tapes decided to focus on three interrelated technologies: materials, design and processing.

“Our goal was to develop a tape technology that was capable of mass production, cost efficiency and reproducibility so every part had the same high quality,” explains Gino Francato, SABIC global composites leader. “We wanted whatever material we produced to process well, be very efficient and mold in a very short cycle time. And since many of our customers were more familiar with metal design, we knew we needed to bring new concepts and design tools.”

Extensive benchmarking clarified that the key parameters for consistently making high-quality, thin tapes with the desired dimensional stability were fiber-spreading and impregnation technologies. Eventually, SABIC connected with Fiber Reinforced Thermoplastics B.V. (Lelystad, Netherlands), which offered much-needed expertise, and SABIC purchased a majority stake in the company in 2015.

Not surprisingly, design and process modeling represented another area of shortfall. While many SABIC customers were comfortable designing with short- and long-glass fiber injection molding grades, continuous-fiber products were a different story, particularly in combination with injection overmolding.

“Industries like automotive and consumer electronics can’t do business with trial and error [make and break] approaches anymore, so they need to know exactly how to predict the behavior of each of these materials and the interaction between them,” explains Scott Davis, SABIC staff scientist-global application technology. That led to an ambitious program within SABIC to develop predictive tools that would work in concert with popular structural and process computer-aided engineering (CAE) tools. Material cards are currently said to be available for finite-element analysis (FEA)-based packages like LS-DYNA (from Livermore Software Development Corp., Livermore, Calif.) and ABAQUS (from Dassault Systèmes, Vélizy-Villacoublay, France).

Another realization that quickly followed was that being able to consistently produce good tapes wouldn’t be enough for such an “underdeveloped” technology, because process engineering know-how and automated equipment to handle tapes at high production speeds weren’t yet at the level the team felt they needed to be.

“We expected that a lot of companies would be able to produce this kind of high-quality product, but that was not the case,” adds Francato. “We checked the industry and looked at a lot of companies, but most were focused on the needs of automotive, and we couldn’t find any that we felt were at the right level — especially to serve the consumer electronics market.” That’s when SABIC’s composite tape team was introduced to Airborne (The Hague, Netherlands), a machine maker and developer of composite processing lines. Airborne had already had success developing equipment to make pipe from thermoplastic tapes for the oil and gas industry. The company also had experience with thermoset tapes in the aerospace industry.

“We felt that Airborne had the same objectives we did,” continues Francato. “They were not just machine builders, they also knew composites and knew the challenges with composites,” he explains. “They had all this experience in automating tape lines but didn’t want to get into materials, and we had the materials expertise but automation wasn’t our area of competency.”

In 2017, SABIC bought a minority stake in Airborne; the two companies worked together to develop the process and equipment necessary to produce thermoplastic tape-based laminates in high volume — millions per year — in a fully automated setting. This system would eventually come to be called the Digital Composites Manufacturing Line (see “High-speed, high-rate thermoplastic composites manufacturing”).

Related Content

Gen 2 Carbon, Americarb launch rCF strategy for clean energy

Combined expertise unlocks novel applications for rCF in batteries, fuel cells, electrolyzers and structural energy storage.

Read MoreTS Conductor to open second AECC conductor facility

TS Conductor is investing $134 million in a new South Carolina manufacturing facility using its aluminum encapsulated carbon core (AECC) conductor technology to produce high-capacity transmission lines, beginning production by late 2025.

Read MoreTeijin lightweight materials enable VAIO portable displays

Teijin's Tenax TPCL and Panlite Sheet materials allow for the creation of complex, three-dimensional shapes in a single molding step.

Read MoreAviation-specific battery system uses advanced composites to address electric, hybrid flight

BOLDair’s composite enclosure, compression structures and thermal runaway management enables high-performance electric energy storage.

Read MoreRead Next

High-speed, high-rate thermoplastic composites manufacturing

A novel process from SABIC and Airborne promises high-speed, high-rate production of thermoplastic composite laminates for mainstream manufacturing and a variety of applications.

Read MoreConsumer electronics: hybrid composite covers

Study demonstrates feasibility of thermoplastic composites, high-speed production process.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read More.jpg;width=70;height=70;mode=crop)