Westlake Plastics, Environmental Composites launch thermoformable carbon fiber composite

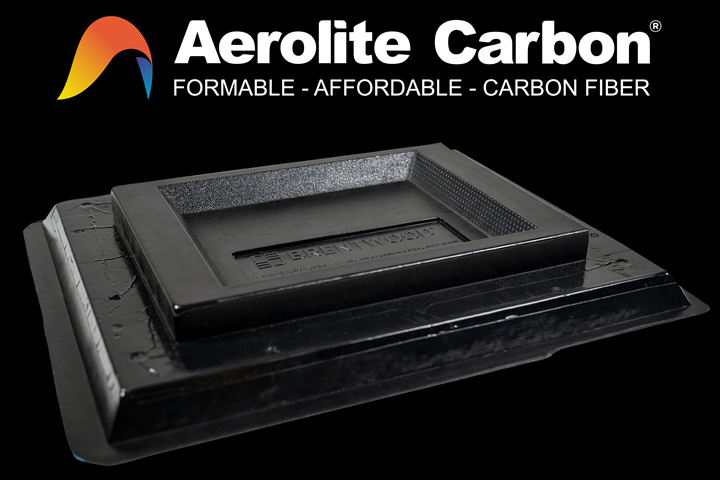

Aerolite Carbon is an advanced carbon fiber/thermoplastic material designed for fast, large-volume parts manufacture on existing equipment.

Source | Environmental Composites Inc.

(Lenni, Pa., U.S.) and (Utica, N.Y., U.S.) have jointly launched Aerolite Carbon, a carbon fiber textile designed for compatibility with standard thermoforming equipment such as vacuum forming or pressure forming.

Aerolite Carbon was developed jointly by thermoplastic extrusion specialist Westlake Plastics and advanced textile specialist Environmental Composites. The product is an advanced carbon fiber textile impregnated with a proprietary thermoplastic alloy resin. According to the companies, the material’s chemistry and construction enables it to stretch uniformly when heated to form deep draws and sharp angles on simple one-sided tooling.

According to the companies, the product supports large-volume applications with standard 4' × 8' sheet size, capable of being processed in under 2 minutes. Aerolite Carbon was developed to deliver better economy and throughput than existing composite materials, while using an existing global supply chain for part conversion. Aerolite Carbon targets both consumer and industrial applications seeking lightweight performance products at minimal cost.

Complex geometry formation and as-molded cosmetic finishes are said to be achievable through a single-step forming process and a proprietary carbon fiber-reinforced sheet design. Color matching, as-molded textures, class A surfaces and custom graphics are also said to be possible with the material.

Related Content

-

Revisiting the OceanGate Titan disaster

A year has passed since the tragic loss of the Titan submersible that claimed the lives of five people. What lessons have been learned from the disaster?

-

JEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

-

Low-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.

.jpg;width=70;height=70;mode=crop)