Techsil, Panacol offer Vitralit adhesive for filament winding

The transparent one-component epoxy adhesive and curing system is ideal for carbon fiber or glass fiber filament winding.

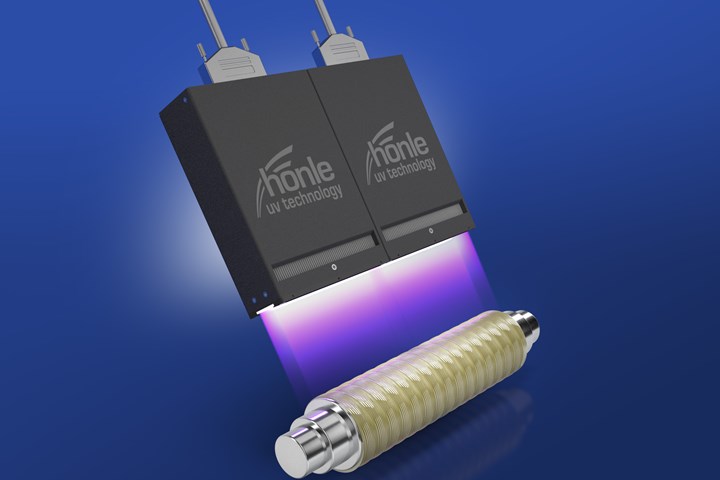

Photo Credit: Panacol-Elosol GmbH

Available through distributor of silicones and adhesive solutions Techsil (Warwickshire, U.K.), Panacol-Elosol GmbH (Steinbach, Germany) offers the Vitralit UD 1405 adhesive and curing system for fiber and filament winding processes, which is said to result in significant time and cost savings. According to Panacol, for high efficiency, the system can be applied during the winding process and immediately cured with high-intensity LED curing systems. The system is also said to be ideal for carbon fiber or glass fiber for filament winding associated with carbon fiber-reinforced polymer (CFRP) or glass fiber-reinforced polymer (GFRP) manufacturing processes. Possible applications include being used to wrap hybrid rotor shafts for electric motors and high-voltage surge arresters.

Vitralit UD 1405 is a transparent, solvent-free, one-component epoxy. Due to its low viscosity, Vitralit UD 1405 is reported to have very good wetting properties. According to Panacol, it can be cured in seconds by irradiation with UV (365-nanometer) or visible (405-nanometer) light wavelengths, and, depending on the fiber material and the wavelength used, layer thicknesses of several millimeters can be achieved exclusively by this light curing. Panacol notes that Vitralit can also be thermally cured after UV exposure to ensure that a complete cure is secured in areas shadowed from the UV light. For example, fibers or filaments can first be pulled through an adhesive bath, then wound onto the rotor or respective cylinder and cured with UV or visible light. A secondary thermal cure will ensure that the layers of coated windings below the surface become fully cured.

Further, after curing, Vitralit UD 1405 is electrically insulating, shows minimal shrinkage and remains resistant at temperatures from -40°C to 180°C. A glass transition temperature of more than 130°C ensures reliable performance even under dynamic load at elevated temperatures.

Techsil also offer an efficient UV curing system for fiber and filament winding processes such as the LED Powerline AC/IC 820 HP from UV specialist Hönle. With intensities of up to 16,000 millwatts per square centimeter (mW/cm²), the LED system is said to ensure very fast curing. Further, its light emission window is available in two standard sizes, 82 millimeters by 20 millimeters and 122 millimeters by 20 millimeters, which can be extended without gaps by stringing together multiple modules.

Related Content

-

Development of a composite liquid hydrogen tank for commercial aircraft

Netherlands consortium advances cryogenic composites testing, tank designs and manufacturing including AFP, hybrid winding, welding of tank components and integrated SHM and H2 sensors for demonstrators in 2025.

-

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

-

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.