Reusable silicone vacuum membrane advances closed composite molding techniques

JEC World 2025: Elkem Silicones showcases its Bluesil RTV 3724 A&B silicone technology, made in collaboration with MVP, for creating durable, reusable vacuum bags.

Source | Elkem Silicones

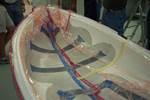

Elkem Silicones (East Brunswick, N.J., U.S.) is showcasing its Bluesil RTV 3724 A&B, a sprayable and brushable platinum cure silicone developed together with Magnum Venus Products (MVP, Knoxville, Tenn., U.S.) to produce high-performance, reusable vacuum bags and advance vacuum infusion molding processes. The product accelerates production, optimizes reusable vacuum bag construction and extends lifespan.

“Sustainability is at the core of our innovation,” says Catherine George, regional marketing manager for industrial assembly and molding at Elkem Silicones. “With Bluesil RTV 3724 A&B, we are not only enhancing efficiency but also reducing waste and environmental impact, enabling manufacturers to meet their sustainability goals without compromising on performance.”

Attendees are able to attend live demonstrations of the technology, which highlight the solution’s application process in which two components are blended and sprayed with MVP equipment. Live demonstrations in Hall 6 include:

- March 4 at 11 a.m. and 3 p.m.: “Mastering Closed Mold Silicone Bag Construction”

- March 5 at 2:30 p.m.: “Achieve Fast Infusion With Grooved Silicone Bag”

- March 6 at 12 p.m.: “Fast Flow LRTM With Skin Mold for High-Quality Parts”

Elkem Silicones provides a full range of silicone technologies for diverse specialty applications including composites.

Visit Elkem Silicones in Booth F126 in Hall 5.

Related Content

-

JEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

-

3D weaving capabilities achieve complex shapes with reduced labor times, costs

JEC World 2025: The specialized engineered woven fabrics company displays film-infused 3D woven joints, woven TPS and woven composite 3D structures.

-

JEC World 2025 highlights: Evolving recycling and biomaterials technologies

CW technical editor Hannah Mason shares sustainability-focused composites trade show highlights featuring maturation, scale-up, new partnerships, and new technologies in biomaterials and recycling.