Plataine releases enhanced version of Digital Thread Portal

The cloud solution delivers digital thread connectivity across multiple sites and organizations, enabling manufacturers to automate material receiving and maintain a complete digital genealogy of their products.

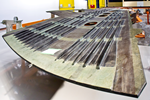

Photo Credit: Plataine

Plataine (Waltham, Mass., U.S.) has released a new version of its, a system that reshapes the way manufacturers manage their materials and streamline their supply chain interactions. The solution increases process efficiencies and fully automates material shipment and receiving, saving operators time and reducing manual errors and delays. The Digital Thread Portal delivers a holistic view of full material genealogy across its entire lifecycle, from raw material to finished part, stretching over multiple sites and organizations across the supply chain.

Plataine says that its solution addresses global supply chain challenges and replaces traditional manual and paper-based processes. The Digital Thread Portal automates and digitizes product life cycle management — from raw material until the finished part. Material suppliers can now log material information and create a Digital Passport of each material shipped, including production and quality attributes of each item and lot, and the production sites receiving the material items can access the same digital information on the cloud and streamline the receiving process, reducing efforts and minimizing any associated human error.

Moreover, the solution recalculates material shelf life (ETL) during its journey across the supply chain, leveraging the condition monitoring information obtained during transit and storage while maximizing material lifetime value and alerting staff on any idle material. This dynamic approach ensures that manufacturers always work with the most up-to-date and accurate data, improving overall operational efficiency. The easy-to-use solution ensures a quick implementation process and high level of user acceptance.

The benefits of Plataine’s enhanced Digital Thread technology extend beyond the factory floor, the company reports. The Digital Thread is now accessible across multiple factory locations, making it easy for manufacturers to track materials across their entire production and supply chain network and improve inventory planning. This seamless accessibility also extends to the communication between suppliers and customers.

Related Content

-

Aitiip concludes HELACS project with waterjet cutting demonstration

Novel platform involving digital twin and human-robot collaboration succeeded in cutting a component from the 19th section of an A350 wing, highlighting its ability to enable composite structure recycling.

-

Siemens software chosen for JetZero BWB aircraft concept, launches Xcelerator updates

Aviation startup will use the Xcelerator platform to achieve its aircraft vision. Other Siemens collaborations deliver software additions to deliver, democratize industrial AI for small companies, startups.

-

How AI is improving composites operations and factory sustainability

Workforce pain points and various logistical challenges are putting operations resilience and flexibility to the test, but Industry 4.0 advancements could be the key to composites manufacturers’ transformation.