Karl Mayer thermoplastic UD tape production line designed for mass production

The SIM.PLY production line is designed for large-scale production of thermoplastic UD tapes for lightweight structural compone

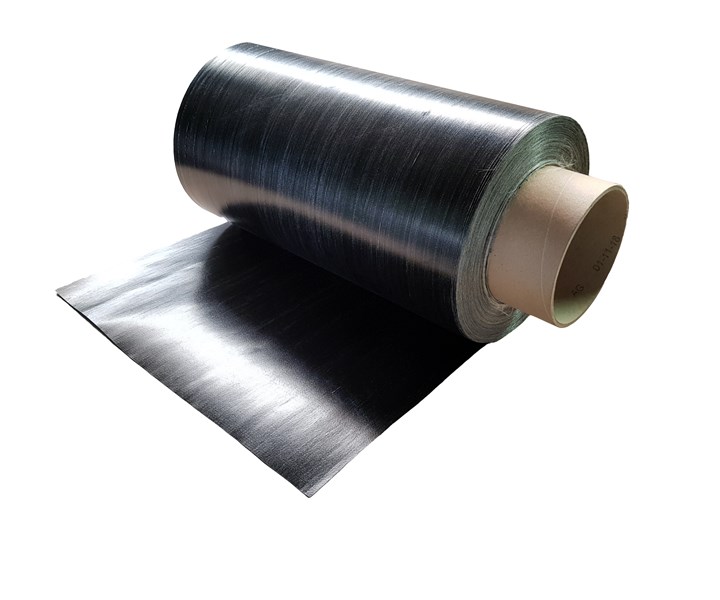

Continuous fiber-reinforced thermoplastic tape made out of glass fiber and polypropylene on Karl Mayer’s SIM.PLY production line. Source | Karl Mayer

Karl Mayer Technische Textilien (Obertshausen, Germany), a specialist in non-crimped fabrics for lightweight structural components, has introduced its latest production line, called SIM.PLY, which produces thermoplastic, unidirectional (UD), fiber-reinforced tapes.

The high-quality tapes, featuring precisely aligned, continuous fibers, are reportedly suitable for use in highly stressed, fiber-reinforced, lightweight structures. The thermoplastic matrix is said to make them easy to process for large-scale production. The SIM.PLY system operates at a high production rate and produces tapes in range of widths.

The company will display this technology at K 2019, Oct. 16-23 in Düsseldorf, Germany.

Related Content

-

MFFD longitudinal seams welded, world's largest CFRTP fuselage successfully completed

Fraunhofer IFAM and partners have completed left and right welds connecting the upper and lower fuselage halves and sent the 8×4-meter full-scale section to ZAL for integration with a cabin crown module and testing.

-

Update: THOR project for industrialized, recyclable thermoplastic composite tanks for hydrogen storage

A look into the tape/liner materials, LATW/recycling processes, design software and new equipment toward commercialization of Type 4.5 tanks.

-

Plant tour: Sekisui Aerospace, Orange City, Iowa, Renton and Sumner, Wash., U.S.

Veteran composites sites use kaizen and innovation culture to expand thermoplastic serial production, 4.0 digitization and new technology for diversified new markets.

.jpg;width=70;height=70;mode=crop)