Johns Manville launches three nylon thermoplastic organosheet product series

The OS-6, NCF-6 and CR-6 series use in-situ polymerization technology for enhanced properties in lightweight structural applications.

Source | Johns Manville

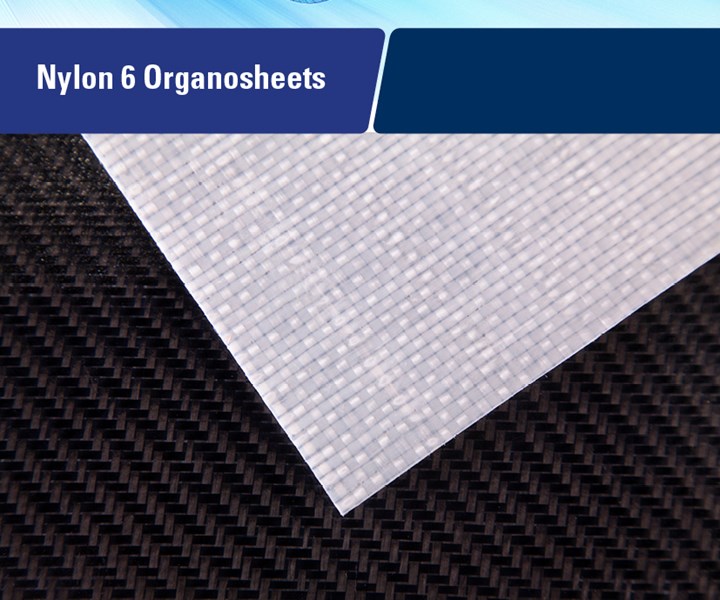

Johns Manville (JM, Denver, Colo., U.S.), manufacturer of continuous filament glass fiber and a Berkshire Hathaway company, has launched three nylon thermoplastic composite product series for lightweight applications: OS-6, NCF-6 and CR-6 series.

The OS-6 series is a nylon composites sheet reinforced with continuous woven fabric and impregnated with the company’s proprietary technology to enhance impact resistance, strength and stiffness in thermoplastic composites.

The CR-6 series is said to use chopped roving reinforcement to combine formability with impact resistance. Its quasi-isotropic properties reportedly enable a range of high-formability applications for thermoplastic sheets.

The NCF-6 series is reinforced with high-density continuous non-crimp fabric to offer high strength, stiffness and impact resistance in structural applications.

The company says its in-situ polymerization technology enables its nylon thermoplastic composite sheets to exhibit superior properties, short cycle times, recyclability and competitive costs.

Related Content

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

-

Low-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.

-

JEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

.jpg;width=70;height=70;mode=crop)