Enhanced Digimat software offers improved composite 3D printing simulation capabilities

Manufacturers are able to analyze the production cost of polymer-based AM parts against conventional processes and validate composite microstructures via CT scanning.

All photo credit: e-Xstream

On Jan. 25 e-Xstream engineering, part of Hexagon’s Manufacturing Intelligence (Luxembourg, U.K.) division introduced new simulation and virtual manufacturing capabilities within its Digimat software that enable users to analyze the production cost of polymer-based additive manufacturing (AM) parts against conventional processes, and continuously improve their virtual engineering processes by validating the composite’s microstructure with computerized tomography (CT) scans of manufactured parts.

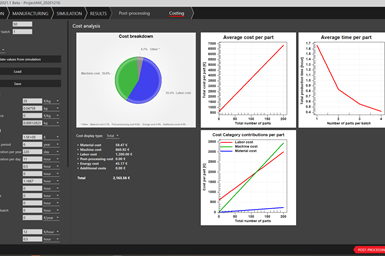

The latest Digimat software enables businesses to simulate the 3D printing process and calculate the total cost of producing each part including the material use, employee time, energy and the required post-processing steps. Using this new tool, e-Xstream says an engineer can take a holistic view of part production and finishing processes to determine the best process chain for production. Crucially, says e-Xstream engineering, it can also be used to perform batch optimizations to print as many parts as possible in parallel, increasing production capacity and reducing lead time. It can also be used in production planning, to consider the total cost of ownership of machines and amortize those costs over the projected production volumes. This information is visualized for the user through plots and pie charts, so the cost breakdown can be easily analyzed for different scenarios.

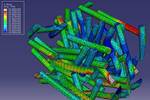

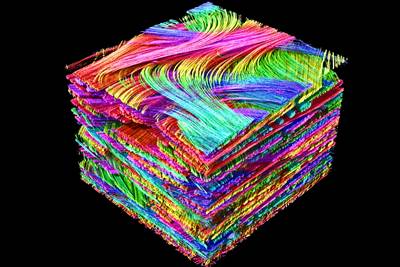

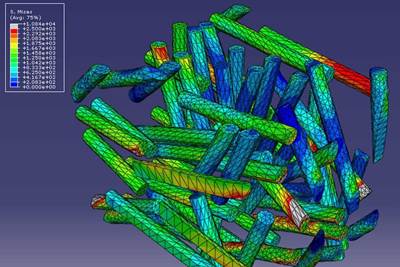

In order to troubleshoot quality issues and improve the accuracy of performance predictions — such as fiber orientation — Digimat now enables manufacturers to CT scan a part and import the 3D RAW image to build a finite element model of its two-phase microstructure (e.g. carbon fiber-reinforced polymer) to perform analyses and model its behavior. Being able to account for variations within a manufactured part could potentially reduce material use or avoid points of failure, e-Xstream says.

Connecting physical measurement with virtual testing is said to also improve the accuracy of Integrated Computational Materials Engineering (ICME) processes when a new material system is introduced; the part performance can be compared to the simulated process to validate and certify the material model. CT scan validation also helps materials professionals refine the microstructure models they have built manually to improve the accuracy of future simulations.

When refining new manufacturing processes, users can capture information about the part, material, 3D printer or process used and their physical tests as they work using material lifecycle management. e-Xstream engineering’s MaterialCenter software — a separate feature from Digimat — captures a traceable, validated database of those trusted material properties so that they can be used in the design phase of a product. Using material lifecycle management, information can be easily documented within multi-disciplinary teams and shared throughout an organization, capturing valuable knowledge for reuse by authorized users.

Optimizing Graphics Processing Units (GPUs) further ensure that some computational tasks, such as analyzing behavior of a CT-scanned microstructure, can now be performed interactively by the engineer with results produced in minutes. Benchmarks show the time required to analyze the stiffness of a material, for example, is reduced by 98%. This rapid solve time, combined with the introduction of a command line interface, also enables the use of Digimat finite element models (FEM) within automated cloud-based optimization workflows on high-performance computing platforms.

Finally, when producing high-performance structures such as aerospace components from composites, the Progressive Failure Analysis (PFA) model makes it possible to define safety margins for a structure and is said to make optimal use of the expensive materials and processes. The latest version of Digimat performs these complex Camanho model analyses twice as fast, making it possible to perform a parametric study to define defect tolerances and maximize production yields.

Related Content

Eaton developing carbon-reinforced PEKK to replace aluminum in aircraft air ducts

3D printable material will meet ESD, flammability and other requirements to allow for flexible manufacturing of ducts, without tooling needed today.

Read MoreHitachi Rail chooses Roboze printers, materials including carbon fiber/PEEK for railway spare parts

The Roboze ARGO 500 will be used at Hitachi Rail factories in Naples, Italy and Maryland, U.S. to reduce cost and delivery times for prototypes and spare parts.

Read MoreOptimizing a CFRP landing leg demonstrator

MT Aerospace achieves design for manufacturing, integrating multiple elements into one-piece structure using AFP and 3D printed tooling to meet time and budget constraints.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreRead Next

Applying CT scan data analysis and visualization to composites

Imaging and analysis via computed tomography (CT) has potential for certifiable safety and business sustainability and could be key for interior inspections of composite parts. Part 1 of a two-part series.

Read MoreHexagon’s e-Xstream engineering presents improved Digimat software

The multi-scale material modeling software enables more comprehensive advanced composite design capabilities.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read More