Electroimpact launches plug-and-play AFP system

Automation and automated fiber and tape placement specialist Electroimpact has introduced Scorpion, a new modular plug-and-play automated fiber placement (AFP) system designed for research and laboratory applications.

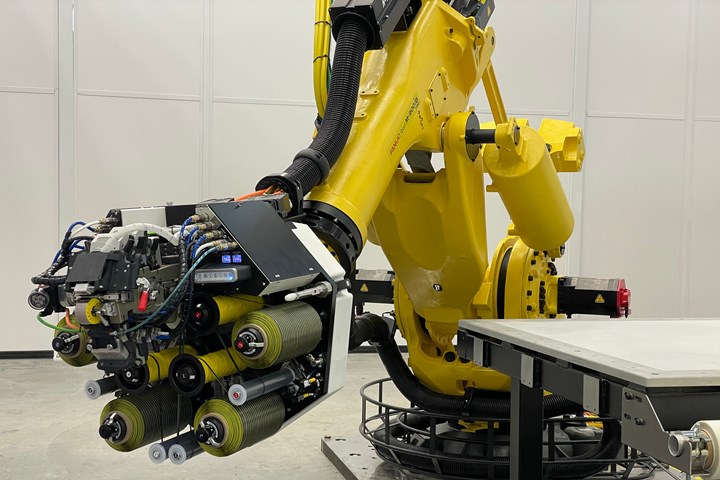

Electroimpact Scorpion automated fiber placement system. Photo Credit: Electroimpact

Automation and automated fiber and tape placement specialist Electroimpact (Mukilteo, Wash., U.S.) has introduced Scorpion, a new modular plug-and-play automated fiber placement (AFP) system designed for research and laboratory applications. Electroimpact calls Scorpion an AFP4.0 system that includes a Fanuc M-900iB/700 robot, a four-lane 0.25-inch AFP head, a 3 x 1.5-meter flat vacuum charge table, a laser safety enclosure and operator interface.

Electroimpact Scorpion automated fiber placement system inside enclosure with vacuum table.

Photo Credit: Electroimpact

The AFP head , which can lay down thermoset or thermoplastic prepreg fiber or dry fiber, features servo-powered creels and offers a two-segment eye-safe laser or a four-segment high-output laser. Speed capabilities include 100 m/min initial feed, 75 m/min refeed and 75 m/min cut. Standard in-process inspection covers tow ends and process errors; optional inspection technologies cover laps/gaps, foreign object debris (FOD) and backer detection. System expansion options include a part rotator, eight- or 16-lane head and 0.125- or 0.5-inch tows.

Related Content

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

-

Reinforcing hollow, 3D printed parts with continuous fiber composites

Spanish startup Reinforce3D’s continuous fiber injection process (CFIP) involves injection of fibers and liquid resin into hollow parts made from any material. Potential applications include sporting goods, aerospace and automotive components, and more.

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.