CompPair healable composites, recycled carbon fibers featured in ID Genève luxury watch

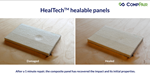

HealTech prepregs enable 400x faster regenerative properties for the new Circular C product, along with incorporation of industrial waste fibers for a sustainable touch.

Photo credit: CompPair, ID Genèva

The newly launched Circular C watch by (Geneva, Switzerland) is claimed to be the first regenerative watch that has been designed with ’ (Renens) healable composite technology, HealTech, produced with prepregs made from recycled carbon fibers sourced from industrial waste.

The dial, side decorations and bezel of the watch are all comprised of HealTech prepregs, which are capable of repairing scratches and internal cracks up to 400x faster than industrial standards. Initially intended for sports, leisure and aerospace components, CompPair’s smart material has also proved its appeal in the luxury sector.

“CompPair’s vision is to extend the lifetime of composites to reduce maintenance operations and waste, as well as improve circularity, in line with ID Genève’s vision,” Amaël Cohades, CEO and cofounder of CompPair, says. “Through this work, we are demonstrating the use of our healable resins with recycled carbon fibers, that can be applied to various other applications."

CompPair aims to accelerate the transition to a circular economy with a product enabling ultrafast repair and cost reductions. The company is developing innovative resins which produce composite structures that can heal damage on-site in 1 minute. Together with ID Genève, CompPair has taken its technology one step further by combining it with recycled fibers, combining innovation with sustainability.

The collection starts with a lab edition limited to a few pieces, before launching a permanent series.

Related Content

-

Composite innovations feature automotive, water sports, UAV and consumer project versatility

JEC World 2025: Precision, performance and reliability are at the core of Cobra International’s display, involving a front end, portfolio of water sports applications, a fixed wing drone and more.

-

Carbon Mobile carbon fiber powers handheld gaming platform

HyRECM technology effectively stabilizes carbon fiber’s electrical and antenna properties, enabling development of next-gen electronics, such as the Snapdragon G3x Gen 2.

-

Toray rCF from Boeing 787 is incorporated into ultra-light laptops

Torayca-based aerospace components have successfully been repurposed into the Lenovo ThinkPad X1 Carbon Gen 12, highlighting the ongoing application of recycled composites.