CAMX 2022 exhibit preview: University of Dayton Research Institute

The University of Dayton Research Institute supports composite manufacturers from the beginning of the design process through first-article fabrication and subsequent testing.

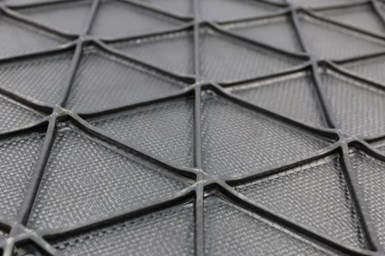

Photo Credit: University of Dayton Research Institute (UDRI)

The (UDRI, Dayton, Ohio) says it has been on the cutting edge of composites advancements for more than 60 years, supporting composites manufacturers from the beginning of the design process through first-article fabrication and subsequent testing.

UDRI owns and operates the Dayton Composite Center, which serves as a demonstration work ell for new composite innovations as well as current best practices. In addition, UDRI has fully equipped labs for mechanical testing (coupon through full structures), non-destructive analysis, additive and subtractive machining and aerospace sustainment. UDRI says its team of more than 700 professionals is available to provide their expertise and experience to any composite-related need.

Related Content

-

VIDEO: Robots enable nine-axis machining of composites

Machine Tool Camp displayed its hybrid machining center at CAMX, featuring nine-axis machining capability enabled by robotics.

-

Highly tunable, woven lattice reinforcements target automotive structures

CAMX 2023: Startup Weav3D will be demonstrating its two collaborative automotive demonstrator parts and present two conference papers.

-

Concentrated smooth dispersion simplifies electrical conductivity applications

CAMX 2024: Total Resin presents Total Nanotüp, a concentrated dispersion of carbon nanotubes in a bifunctional reactive monomer for polyester, vinyl ester, melamine and acrylic resins.