CAMX 2021 exhibit preview: Wickert

Wickert USA’s hydraulic and fully automated press systems are capable of achieving pressing forces between 2-10,000 metric tons. They are used to process composites, elastomers, plastics and powder materials.

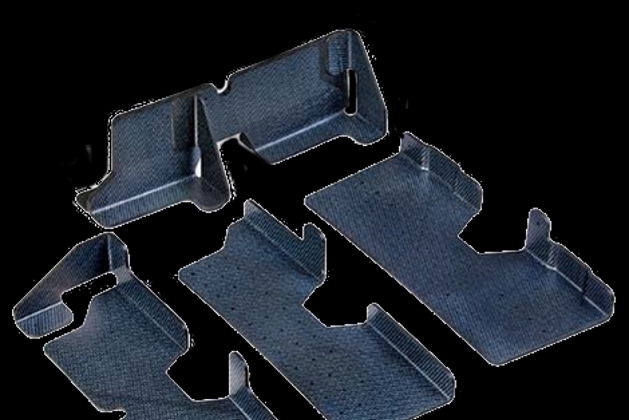

Wickert’s 3D-shaped clips. Photo Credit: Wickert USA

Wickert Hydraulic Presses USA (Hebron, Ky., U.S.) develops and manufactures custom hydraulic presses and fully automated press systems, which the company is showcasing at CAMX 2021. According to Wickert, all its machines and systems have a modular footprint and feature pressing forces of between 2-10,000 metric tons. The systems are used to process composites, elastomers, plastics and powder materials.

A core product for Wickert is hydraulic composites presses for forming fiber composites. Composites presses from Wickert are available with various process technologies such as compression, thermoforming or injection; they are also offered as turnkey, fully automated systems.

Wickert’s four-column composites press, with fully hydraulic closing system and active parallelism control, offers a maximum deviation of 0.05 mm during the pressing process. It has a 59″ x 79″ clamping plate and is characterized by its opening and closing speed of 300 mm/s, a press speed of 10 mm/s and an opening force of 37 tons. The press integrates with a robot, which handles the material from the furnace into the die and ensures that the production process runs smoothly.

Wickert also developed a fully automated production cell. This cell houses a press with a magnetic mold clamping system, automatic release agent spraying the mold and a special press design to compensate for eccentric loads. Additionally, the press is assisted by a robot with a gripping system for product manipulation, and an additional robot for mold manipulation and mold change.

Related Content

-

VIDEO: High-rate composites production for aerospace

Westlake Epoxy’s process on display at CAMX 2024 reduces cycle time from hours to just 15 minutes.

-

Exacting chemistry streamlines composite surface prep

CAMX 2025: Hawkeye Industries exhibits Duratec, Styrosafe, Styroshield and Aqua-Buff brands for optimal composites coating, compounds and polish solutions options.

-

Automated RTM, SQRTM enhance aerospace composites serial production transition

CAMX 2025: Coexpair, in partnership with Radius Engineering, combines equipment development and fabrication with engineering of composite parts, demonstrated in its European customer support, deliveries.