CAMX 2021 exhibit preview: Europe Technologies

Europe Technologies highlights its robotic finishing cells and ultrasonic cutting solutions.

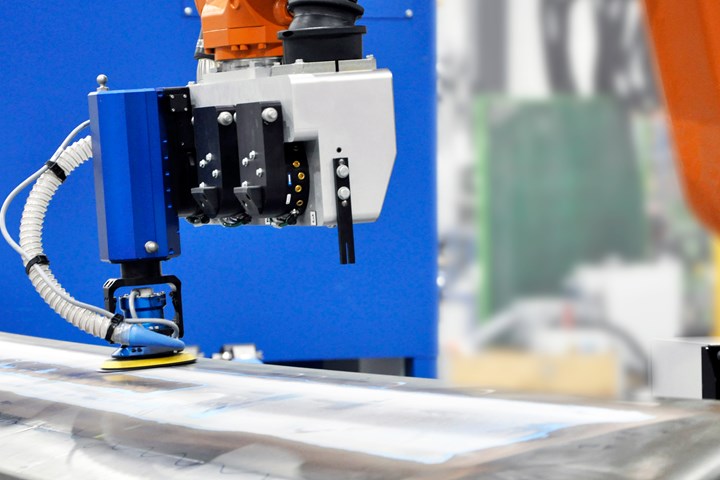

GEBE2 robotic composite finishing cell. Photo Credit, all images: Europe Technologies

Exhibiting at the booth, (Carquefou, France) highlights its adaptive composites manufacturing and finishing solutions, particularly its GEBE2 robotic machining cells and SONIMAT ultrasonic cutting solutions. The company provides robotized processes for sanding and acoustic drilling, as well as handheld systems and embeddable end effectors for ultrasonic cutting and welding.

GEBE2 brand solutions include robotic finishing cells with multi-spindle heads, for greater flexibility and reduced costs compared to conventional machines. A second robot can be added to change over drill bits for additional autonomy.

Another optional add-on for GEBE2 is a smart end effector for sanding operations. Designed to replace manual sanding efforts and to increase quality and consistency, the end effector is equipped with a random orbital electric sander and a compliant device that applies a constant force in all directions.

SONIMAT ultrasonic cutting solution.

In addition, Europe Technologies and (Marnaz, France) have partnered on a robotized potted-in insert solution for composite sandwich panels. Part of the GEBE2 brand, this solution was designed to solve challenges in lightweighting automotive parts and to replace conventionally manual fixing processes for sandwich panels. The robotized potted-in insert solution is said to automate, simplify and facilitate the fixing of composite and metal honeycomb sandwich panels, including Nomex and aluminum.

The SONIMAT brand has been providing ultrasonic cutting solutions for composite materials for more than 25 years. Advantages include no fraying, reduced cutting effort, increased blade lifetime and cauterization of products and SONIMAT is said to fit manual or automated needs. The technology is available in a portable system or with a range of end effectors such as robotic cells, CNC machines and XY tables.

Related Content

-

Otto Aviation launches Phantom 3500 business jet with all-composite airframe from Leonardo

Promising 60% less fuel burn and 90% less emissions using SAF, the super-laminar flow design with windowless fuselage will be built using RTM in Florida facility with certification slated for 2030.

-

Reinforcing hollow, 3D printed parts with continuous fiber composites

Spanish startup Reinforce3D’s continuous fiber injection process (CFIP) involves injection of fibers and liquid resin into hollow parts made from any material. Potential applications include sporting goods, aerospace and automotive components, and more.

-

Carbon fiber composite pallet revolutionizes freight industry

LOG Point Pallet fuses advanced materials with innovative design and manufacturing to improve supply chains worldwide.

.jpg;width=70;height=70;mode=crop)