CAMX 2019 exhibit preview: MSC Software

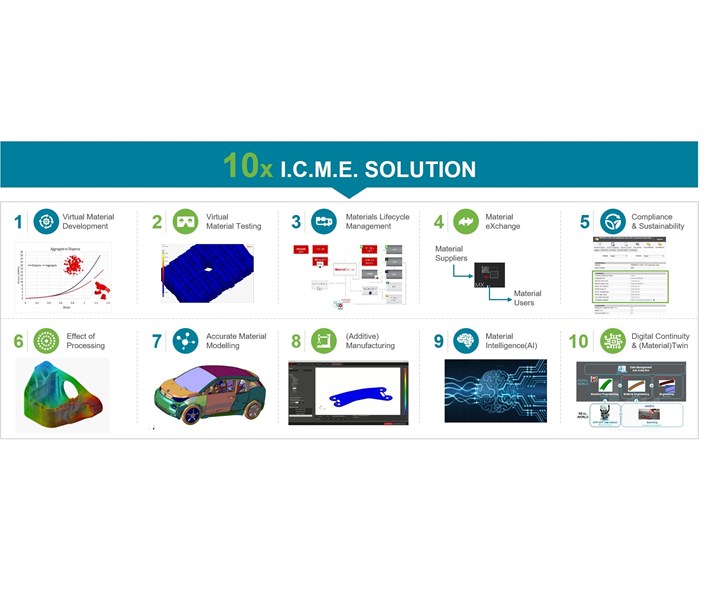

MSC Software is featuring its 10x Integrated Computational Material Engineering (ICME) Solution at CAMX 2019.

MSC Software (Newport Beach, Calif., U.S.) is featuring its 10x Integrated Computational Material Engineering (ICME) Solution, a simulation platform developed to address business and engineering challenges in the materials development and utilization process.

The 10x ICME Solution is developed to address ten challenges:

- Virtual material development: Different mixtures or combinations of material constituents at the micro scale can be simulated with the 10x ICME Solution.

- Virtual material testing: Characterizing a composite material can take 2-3 years of testing, involving testing numerous coupons. This solution is available to simulate coupon tests virtually.

- Materials lifecycle management: This solution stores, protects, manages and distributes material data, as an alternative to storing data in PDF or Excel files that can become difficult to track.

- Material exchange: A solution is available that makes the supplier’s proprietary material models available in an encrypted manner and allows for subsequent engineering analysis by end users.

- Compliance and sustainability: The 10x ICME Solution features iPoint integration allowing for compliance reporting.

- Effect of processing: Mechanical simulations created using this tool incorporate critical details such as fiber distributions and orientations, for greater accuracy of the part’s performance.

- Accurate material modeling: A manufactured part composed of engineered materials must be validated to perform well during service. The 10x ICME Solution provides more accurate material models to support Finite Element Analysis (FEA) used during the validation process.

- Additive manufacturing (AM): Simulation of the AM material, process and printed part performance is said to minimize costly physical prototypes.

- Material intelligence (AI): AI methods embedded in the 10x ICME Solution improve the material development, selection and utilization process.

- Digital continuity and material twin: An extensive suite of simulation equivalents are available for material development, material characterization, manufacturing simulation and final part performance. A digital twin of the material manufacturing process is obtained and improves predictability.

The 10x ICME Solution is said to apply to a range of materials including composites, plastics and ceramics, and works alongside manufacturing processes such as injection molding, automatic fiber placement (AFP) and additive manufacturing.

Related Content

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

-

Bladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

-

Damage tolerance testing of sandwich composites: The sandwich CAI test

A new ASTM-standardized test method established in 2022 assesses the compression-loaded damage tolerance of sandwich composites.

.jpg;width=70;height=70;mode=crop)